AUTOMATED PARTS WASHERS

Leverage cutting-edge automation to help reduce labor requirements

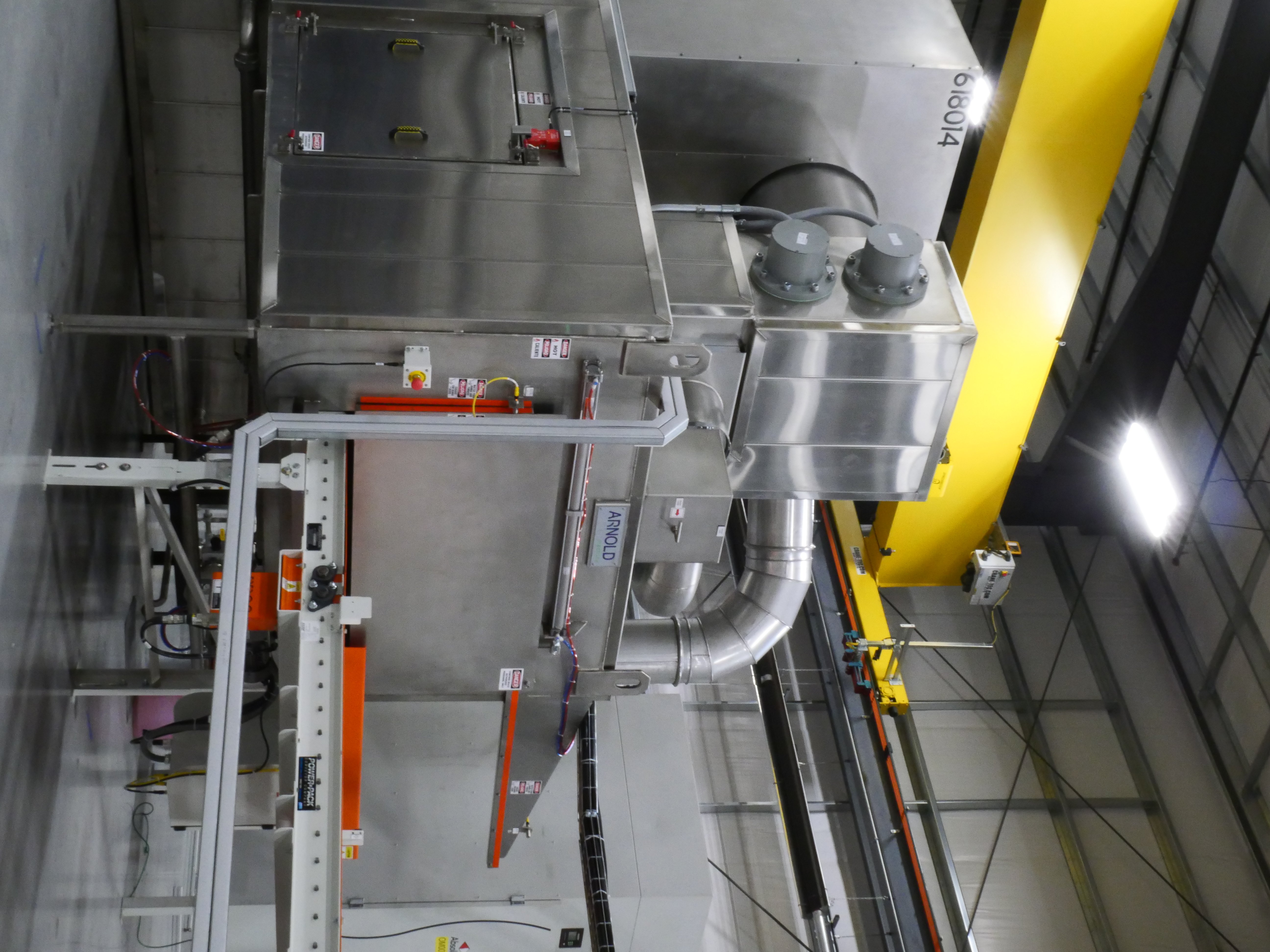

Arnold Machine can add automation features to most of our industrial parts washers. Options include conveyor systems, robotic arms, and automated carts to handle part loading and unloading.

Manufacturers can optimize labor more effectively when they automate the parts washer loading and unloading step. Operators need only be present at the start and finish of each cycle. This frees up their time to focus on higher-priority tasks.

The right automation improves workflow efficiency, increases output, and cuts costs. Let Arnold Machine's automated parts washers take your manufacturing productivity to the next level and beyond.

PARTS WASHING AUTOMATION BENEFITS

Eliminate Contamination Risk

Ensures consistently clean parts while avoiding the potential for contamination.

Reduced Labor Requirements

Allows operators to load the washer and walk away to handle other tasks.

Increased Employee Safety

Automated cleaning minimizes worker exposure to hazardous chemicals.

Give us a call today to discuss the right machine for your cleaning needs, or request a quote using our online quoting form.

Conveyor System Washers

Ideal for In-Line, High-Volume Production. Get high-volume washing with Arnold's customizable conveyor systems. Achieve multi-stage methods and transport tailored to your parts and process.

Immersion

Versatile and Effective Cleaning. Arnold Machine immersion parts washers offer versatile and practical cleaning solutions tailored to your most demanding applications. These units are ideal for precision cleaning, oil removal, and more.

Rotary Table

Ideal for Low-Volume Parts Washing. Our rotary table washers tackle diverse parts-cleaning challenges with unmatched durability. Perfect for low-volume and batch cleaning, these machines adapt quickly to different part sizes and shapes. Choose from customizable features like heated wash and rinse cycles.

Rotary Basket

Multiple Available Configurations. Rotary basket washers offer flexibility for all your parts-cleaning challenges. These machines are an excellent fit for batch, precision, and ultrasonic cleaning. You can choose from various basket capacities and cleaning methods, from spray to full immersion.

ADDITIONAL AUTOMATION DETAILS

Industrial parts washers from Arnold Machine offer robust engineering, high-quality parts, and unmatched reliability. This allows manufacturers to improve operational efficiency and reduce maintenance downtime across production lines.

We can outfit most of our custom washers with some form of automation. For example, we can automate the chemical addition process and the loading and unloading of materials in and out of the washer.

Automatic parts washers can significantly improve material flow. This is especially true if the washer is part of a larger process, such as cleaning before or after a welding operation.

Washing automation is also beneficial before a coating application, particularly in processes requiring anti-corrosive spraying. It helps to remove oil and grease and prevents contamination from fingerprints, dirt, or debris.

COMBINING AUTOMATION AND PARTS WASHING

Watch the video below to see the automated parts washer Arnold Machine built for a manufacturing company. The customized washer helped our client to tighten quality control and reduce labor needs.

Get in Touch With Us

Contact us below to speak with one of our engineers. We’ll take the time to learn more about your processes so we can make custom recommendations that meet your unique needs and solve your toughest challenges.

Request a Quote Contact UsFrequently Asked Questions

-

What types of materials can your parts washers clean effectively?

-

How can I customize my parts washer system beyond adding automation?

FEATURED POSTS

Automated Transmission Washer & Conveyor System

This case study details the high-quality build, add-on features, and impeccable design of a transmission parts washer Arnold developed for a global production engineering company.

Six Common Problems with Washing Parts

Find out how to identify and resolve six of the most frequent problems you may experience with an industrial parts washer.

[Case Study] Combining Automation and Parts Washing

See how we assisted a firearms and ammunition maker to wash their magazines more efficiently after stamping.