Automated Spray Coating Systems

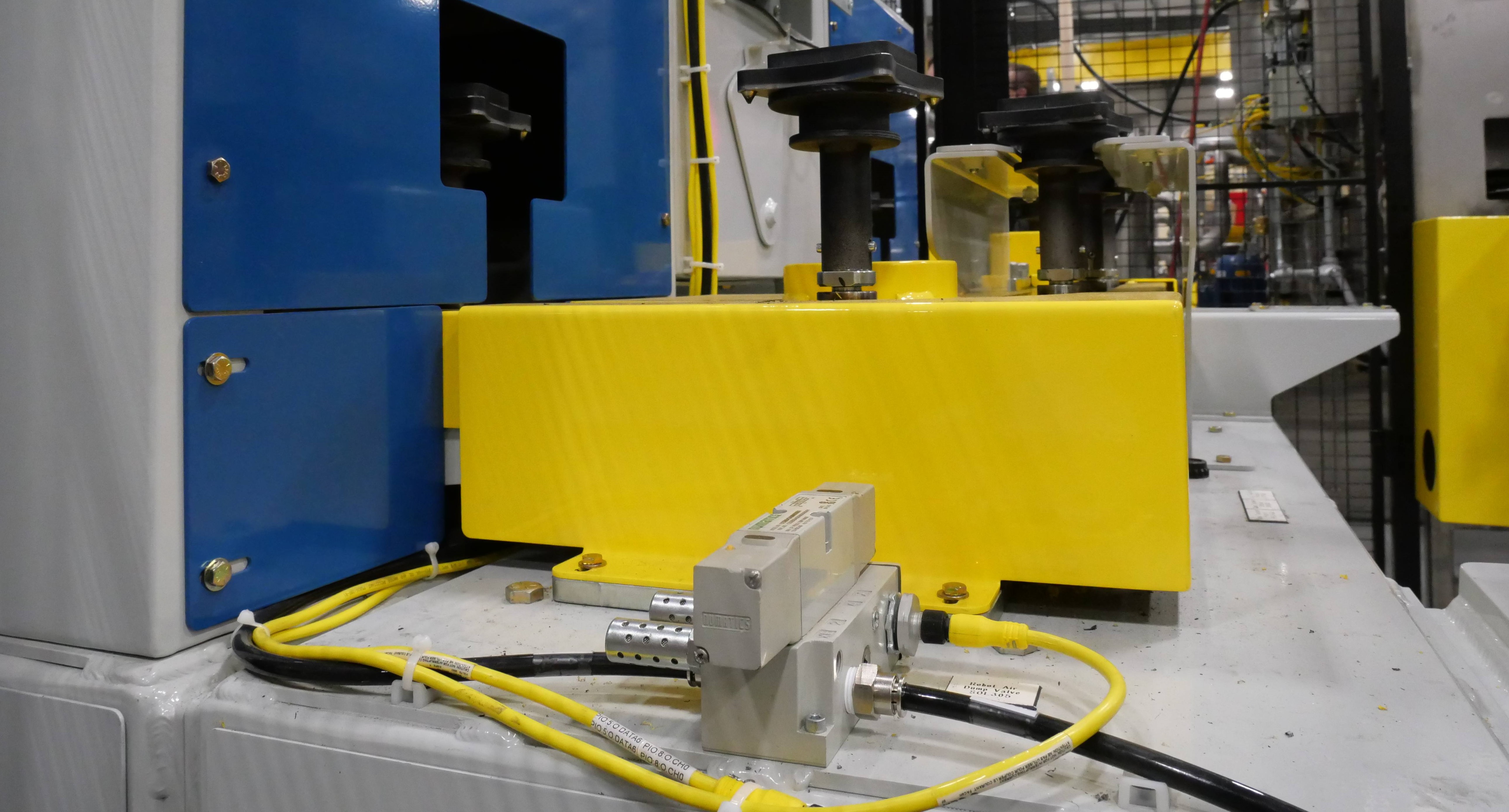

Arnold Machine specializes in customized robotic and automated spray systems that precisely apply adhesives and coatings to parts.

Automating wet paint and adhesive spraying processes improves uniformity and reduces material waste. It also provides significant labor savings compared to manual spraying.

Recipe-based settings eliminate operator setup errors and allow for repeatable results. Our equipment options support batch or continuous processing to match your production needs.

The enclosed spray booths ensure a controlled airflow environment. This minimizes overspray and protects operators from harmful VOC exposure.

These features work together to ensure efficient, safe, and high-quality coating operations.

Benefits of Automated Spray Coating Systems

Our Automated Spray Coating Systems & Bulk Mixing Stations

Chain-on-Edge Conveyors

Our CoE solutions deliver unparalleled efficiency to revolutionize your operations.

Intelligent automation optimizes material flow, reduces labor costs, and maximizes your return on investment.

Tumble Spray Coating Systems

Achieve flawless coating with our automated Tumble Spray Systems. Eliminate wasted labor, maximize efficiency, and ensure consistent coverage.

Roll Coater Systems

Maximize production and minimize waste with our high-throughput coating systems. Achieve superior results and seamless integration with your existing processes.

Interior Diameter (ID) Tube Spray Machines

Optimize your internal tube coating process for maximum efficiency and reduced material costs. With an automated system, achieve superior safety and high-quality finishes.

Automatic Viscosity Bulk Mixing Stations

Streamline your coating process and maximize uptime with automated viscosity control. Ensure reliable, consistent mixing without manual intervention.

How to Choose the Right Automated Spray Coating System

Selecting the right automated spray coating system for your production line requires careful consideration. Here are the key factors to keep in mind:

- Throughput Capability: We can adjust our automated paint spray systems to match your part size, coverage needs, and high production throughput goals. Consider these factors when evaluating a system's potential cost-effectiveness.

- Expertise and Technology: Partner with an experienced manufacturer who offers the latest technology tracking material usage, waste reduction, and part quality control.

- PLC Integration: Choose a system with a PLC (Programmable Logic Controller) to track critical process data. This ensures consistent coating quality and allows you to trace results for future improvement.

- Safety and Environmental Compliance: When working with solvent-based materials, ensure the system meets all safety and environmental regulations.

- Automation vs. Robots: Robotic systems generally offer greater flexibility in spray gun positioning, achieving higher transfer efficiency and reducing changeover times. Compare robotic and automated systems based on your current and potential future needs.

- Batch vs. Continuous Processing: All of Arnold Machine's spray systems are suitable for batch processing. Consider options to improve efficiency if you have frequent changeovers due to a diverse product mix. Evaluate continuous operation systems to see if they meet your production needs.

Arnold Machine offers four primary spray system classifications along with complementary equipment to create a fully integrated setup:

Index spray machines and chain-on-edge spray machines: These versatile systems coat round parts on their inside or outside diameters. The machine rotates parts during spraying, allowing for precise coverage with a stationary spray gun. Index spray machines have fewer part fixtures and spindles for longer cycle times. Alternatively, chain-on-edge machines allow for shorter cycles with a continuous or indexing motion.

Interior diameter (ID) tube spray machines: These machines are built specifically for coating very long tubes (up to 40 feet!). Temperature-controlled drying ensures complete interior coverage with faster cycle times and reduced material waste.

Tumble spray adhesive automation lines: Our tumble spray lines address shortcomings in traditional dip lines and are ideal for oddly shaped parts requiring total exterior coverage. Unlike index spray machines, tumble spray lines avoid witness marks.

Automatic viscosity bulk mixing stations: These complementary stations can integrate seamlessly with the spray systems we offer. Each station maximizes viscosity consistency while streamlining operation and offering complete process control.

Customized Spray Systems Designed for Paint & Adhesives

Our automated spray coating systems expertly handle both adhesives and paints. We prioritize safety features to manage the solvent-based nature of many adhesives. Precise temperature control ensures consistent dry film thickness, even with multiple coats of primers and adhesives.

Some paints may require slightly larger spray gun nozzles due to their thicker viscosity. However, the benefits of these systems remain the same for both types of materials.

Automated Spray Systems that Focus on Safety & Process Control

At Arnold Machine, we understand that safety and efficiency are paramount in your manufacturing process. That's why we design Automated Spray Systems with integrated safety features and precise process control. Our engineers will customize a system to your exact specifications, optimizing material usage, reducing cycle times, and ensuring a safe work environment.

Our systems prioritize safety with features like interlocked spray booth doors, part sensors, over-temperature controllers, and airflow monitoring. Safety pull cords and manual/automatic fire suppression options are also available in operator work areas.

We currently offer two coating machines – automated and robotic – to give you superior control over your process. All systems feature automated temperature control, rotation speed, spray time, fan and atomization pressure, and gun positioning. For intricate patterns, robotic systems enhance automation with robots that precisely manipulate spray guns.

Every system features process control capabilities to monitor adhesive viscosity, control substrate temperatures, adjust air and fluid pressures, and ensure repeatable spray gun setups. These systems also recirculate material to reduce downtime and prevent chemicals from blocking lines or guns.

Trust Arnold Machine with Your Coating System Needs

For over 24 years, Arnold Machine has been a leader in the coating industry. Our experienced engineers will collaborate closely with you to understand your unique needs. They will design a customized system that delivers exceptional results. Enjoy years of reliable coating system performance backed by cutting-edge technology and our commitment to quality.

Automated Spray Coating System FAQ

-

My parts vary greatly in size and shape. Can automatic spray coating machines handle this kind of diversity?

-

How does an automated paint sprayer system affect the work environment compared to manual spraying?

-

I'm concerned about the complexity of transitioning to an automated system. What support do you offer?

Featured Posts

Minimizing the Cost of Automatic Coating Systems With Machine-as-a-Service

Discover a new way to upgrade your coating technology with MaaS. Access cutting-edge systems, reduce upfront costs, and improve your financial flexibility.

Choosing the Right Paint Conveyor System: Factors to Consider

Choose the right paint conveyor system for your needs. Learn what factors to consider for optimal quality, efficiency, cost-savings, and safety.

How Much Does a Chain-on-edge Paint Line Cost?

Learn how to upgrade your paint line without breaking the bank. Explore the costs of a Chain-on-Edge system and alternative financing options.