GLADIATOR 911 - FIREFIGHTER GEAR WASHERS

Durable Gear Washers Built to Last

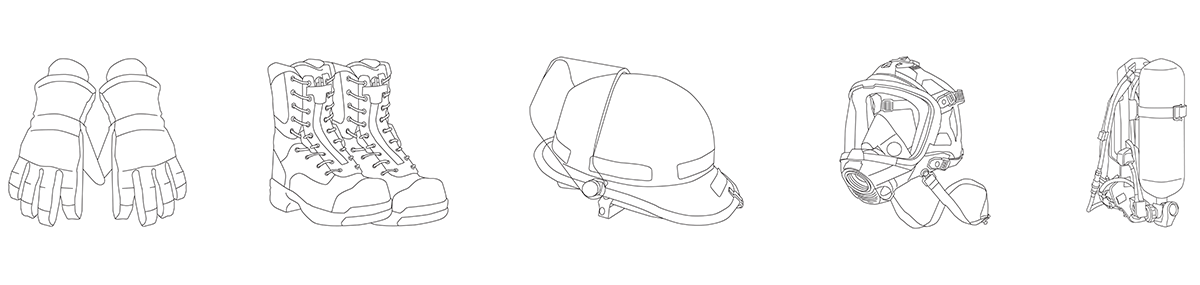

Cleaning firefighting gear is tough, but the Gladiator 911 PPE Washer is tougher. It reduces the need for hand scrubbing and minimizes exposure to potential contaminants from helmets, tools, boots, gloves, and SCBA gear.

The Gladiator 911 combines rust-proof 304 stainless steel with high-quality components for maximum durability and reliability. A lifetime guarantee on the shell and two-year parts warranty ensure long-lasting performance.

When it comes to keeping firefighting gear in safe and pristine condition—you battle the blazes; we'll handle the cleanup.

GLADIATOR 911 PPE WASHER BENEFITS

✔

Rugged and Durable

Built tough to withstand heavy daily use and perform flawlessly over the long haul.

✔

User-Friendly Design

Carefully engineered for simple operation and maintenance. Just load and start washing.

✔

Lab-Tested Engineering

We partnered with a specialized chemist and environmental lab to ensure optimal contaminate cleaning.

ADDITIONAL GLADIATOR 911 DETAILS

Washing your gear after a fire is one of the most important things you can do to minimize toxin exposure. The Gladiator 911 PPE Washer makes the task simple, thorough, and efficient.

Arnold Machine engineers worked closely with firefighting gear manufacturers while designing the Gladiator 911. That collaboration enabled us to develop a bunker gear washer that thoroughly cleans without degrading the material integrity and longevity.

We engineered the Gladiator to optimally clean turnout gear and other safety equipment. However, it’s not a washing machine and cannot clean regular clothing or fabrics (e.g., suits/jackets/pants).

The spacious interior holds a complete set of protective gear for one firefighter. Or you can fill it with different combinations and pairs of boots, helmets, SCBA tanks, and face masks to customize each wash.

How it Works

The Gladiator 911 makes it easy to load and unload firefighting gear. Hooks and fixtures securely hold PPE, allowing for a safe and efficient cleaning process. The intuitive operation saves time for your busy fire department crew.

The system provides 45 gallons of cleaning solution per minute at 40 psi. This high-pressure flow thoroughly sprays gear from all angles as the internal wash table rotates 360 degrees.

After washing, a rinse cycle lightly sprays gear to remove any remaining residue from the contaminated equipment. The wash table continues turning during rinsing. Once completed, the washer automatically meters the proper amount of solution back into the tank.

Maintenance

There’s minimal maintenance and cleaning required. You’ll only need to replace the bag filter as needed. After draining the tank, spray off and clean the components before refilling.

Made in the U.S.A

Arnold Machine engineers and manufactures our turnout gear washers at our Tiffin, Ohio, facility. All major parts (heater, pump, and drive) are USA-made. We offer a lifetime guarantee on the washer shell and a two-year warranty on all major components.

GLADIATOR 911 TECHNICAL INFORMATION

Each Gladiator 911 PPE Washer has a simple HMI (human-machine interface) screen. All the operator needs to do is press the cycle start button on the HMI screen. The wash program cycle will begin and last until complete. They can then remove the cleaned PPE gear.

There are (3) user-adjustable HMI timers that the operator can modify to customize each wash:

- Cycle time

- Chemical addition time

- Freshwater rinse time

The stainless steel filter housing has a stainless steel bag filter, making changing it easy and affordable. This innovative design also allows departments to recycle water and minimize usage.

Other Gladiator 911 SCBA Washer technical specs include:

- Wastewater pump-out

- Automatic chemical addition pump

- Debris Basket catches large debris and prevents it from entering back into the wash cycle. This design helps to protect the pump head while increasing the filter lifecycle.

SEE THE GLADIATOR 911 IN ACTION

Watch the Gladiator 911 perform a complete cleaning cycle. The powerful yet gentle washer keeps firefighting gear contaminant-free and ready for the next call.

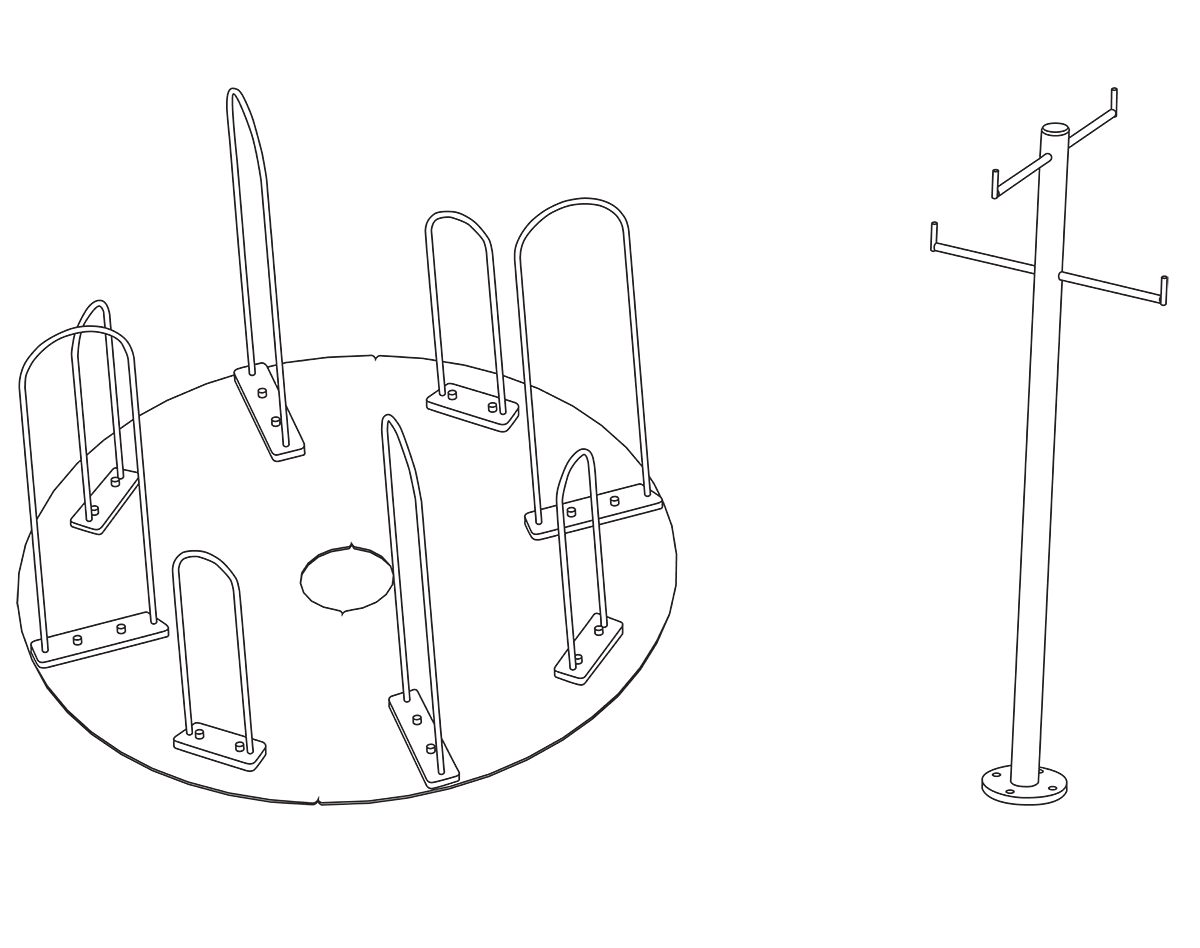

Gladiator 911 - Interior Accessories

All Gladiator 911 washers come with a parts tree for face masks, tanks and helmets. It also includes an insert for boots.

Optional additions include small parts (Kadon) baskets to wash small parts and tools.

FIREFIGHTER GEAR WASHER TECHNICAL SPECIFICATIONS

Standard Mechanical Equipment

- Waste Water Pump Out

- Chemical Addition Pump

- Stainless Steel Vertical Solution Pump

- Stainless Steel Screw Plug Heater

- Stainless Steel Perforated Debris Basket

- Industrial Duty Gearmotor

- Threaded Poly Spray Nozzles

- 1" Brass Drain Valve

- Viewing Window

- Casters

- 6" Tall Stainless Steel Containment Ring

- Stainless Steel Bag Filter

Standard Electrical Equipment

- NEMA 12 Controls Enclosure

- Low Level Heater/Pump Protection

- Thermostatic Heater Control

- Door Safety Switch

- Wash Stage Timer (HMI controlled)

- Rinse Stage Timer (HMI controlled)

- Chemical Addition Timer (HMI controlled)

Options

- Stainless Steel Spray Nozzles

- Kadon (Small Parts) Baskets (18"x12"x6")

- 240V 3PH

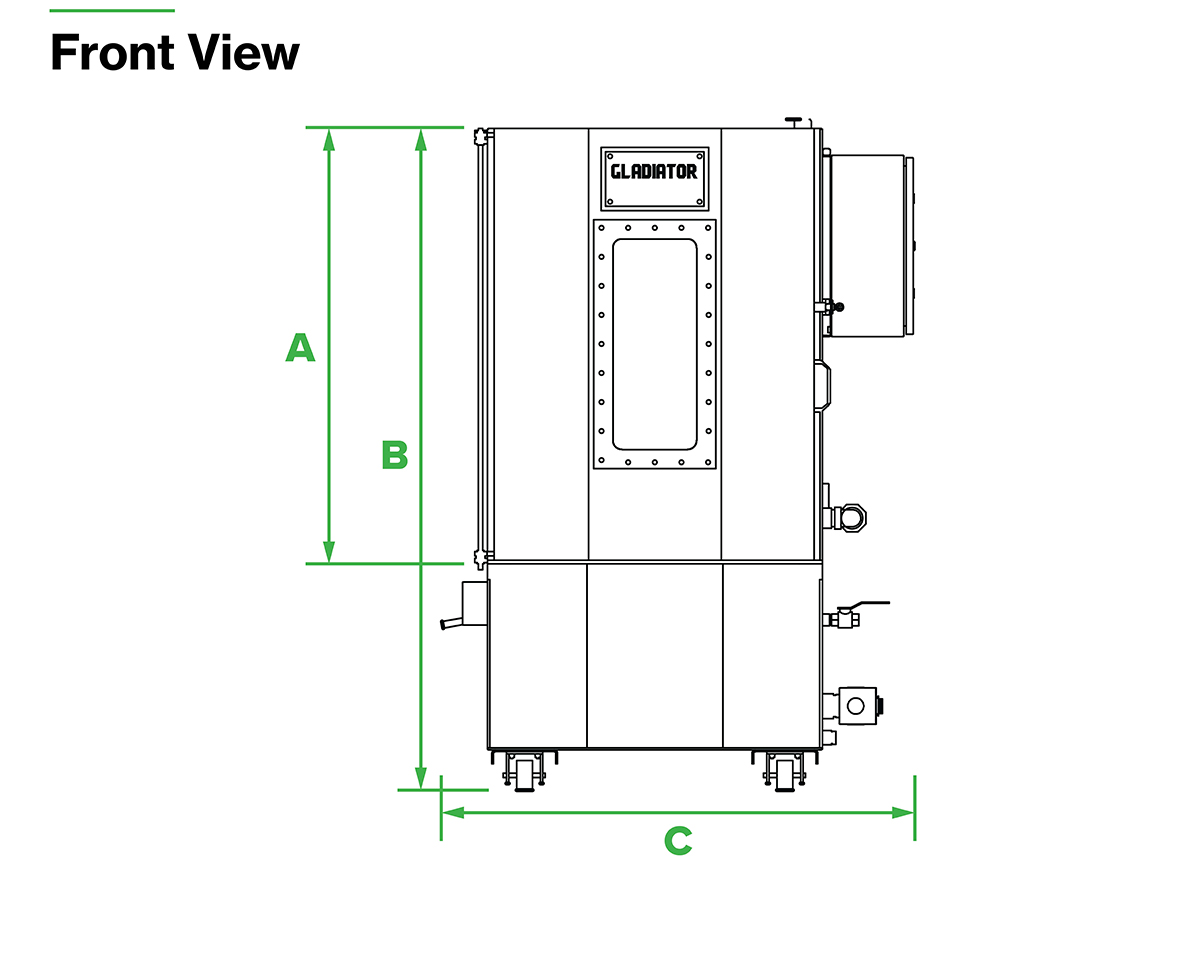

| Table Diameter (IN) | 30 | Tank Capacity (GAL) | 55 |

| Part Opening Height (IN) - A | 36 | Tank Heater (KW) | 9 |

| Load Height (IN) | 30 | Heater Amps (240 1PH) | 41.2 |

| Table Load Capacity (LB) | 1000 | Heater Amps (240 3PH) | 24.8 |

| Table Speed (RPM) | 2.5 | Tank Operating Temp (F) | 120 (F) Recommended |

| Drive (HP) | 1/4 | Tank Heat-Up Time (To 120F)(HRS) | 0.5 |

| Drive AMPS (240V 1PH) | 2.9 | Standard Voltage | 240V 1PH |

| Drive AMPS (240V 3PH) | 1 | Housing Construction | 12 ga. 304 Stainless Steel |

| Pump Flow (GPM) | 45 | Height (IN)—B | 6'-2" |

| Pump Pressure (PSI) | 40 | Width (IN)—C | 4'-6" |

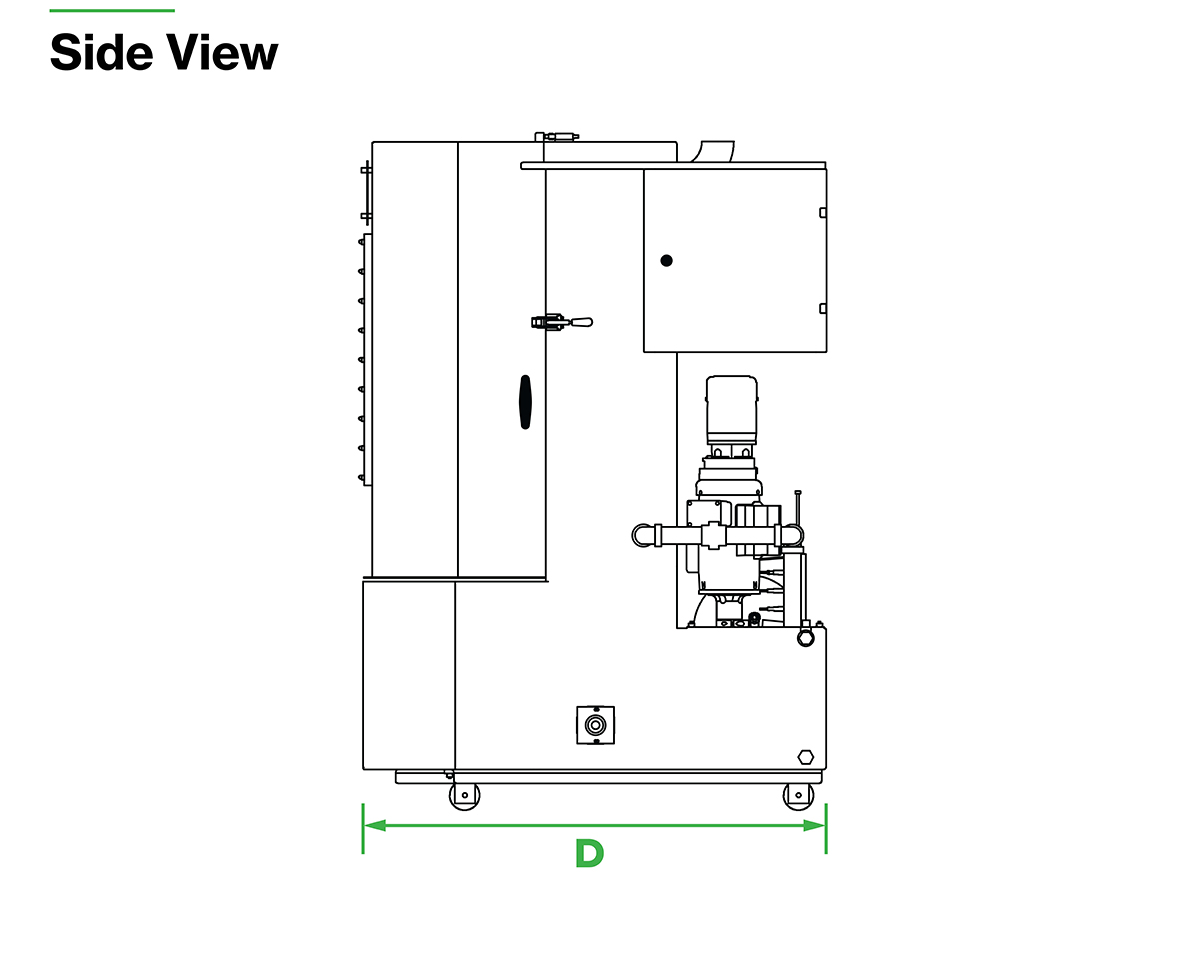

| Pump (HP) | 3 | Depth (IN)—D | 4'-3" |

| Pump Amps (240V 1PH) | 17 | Full Load Amps (240V 1PH) | 61.1 |

| Pump Amps (240V 3PH) | 9.6 | Full Load Amps (240V 3PH) | 35.4 |

Quality Assurance

We offer a lifetime guarantee on the 304 stainless-steel exteriors of the Gladiator parts washers. Unlike carbon steel washers, the Gladiator 911 won't rust and is highly resistant to corrosion and oxidization. The heater, drive motor, and pump are the three main replaceable parts of the Gladiator washer.

Arnold Machine offers up to a 2-year warranty after the purchase and will replace and repair at no cost during this period. We only use top-of-the-line industrial components built to last in a production/industrial setting. Quality and longevity come first when selecting suppliers.

FREQUENTLY ASKED QUESTIONS

-

How is your turnout gear washer different from a standard washing machine?

-

What sizes of gear can this washer handle?

-

Do I need special detergents to operate the Gladiator 911 washer?

See our resources—or case studies below—to help you in the research process.

FEATURED POSTS

[Case Study] Road Maintenance Parts Washer

Discover how we helped a large Department of Transportation entity solve an even larger parts washing challenge.

Parts Washer vs. Manual Cleaning

Read about the many benefits an industrial parts washer offers over manual cleaning.

How Much Does an Industrial Parts Washer Cost?

Learn about the various factors contributing to the overall cost of an industrial parts washer.