Driving ROI with Efficient Adhesive Spray Coating

How Automating Spray Applications Can Increase Efficiency and Profitability in the Aerospace, Automotive, Oil and Gas, and Heavy Equipment Industry

In the manufacturing sector, smart choices lead to higher profits. Discover how optimizing adhesive spray application can improve your ROI and efficiency, making your business more successful.

Key Takeaways:

-

Boost Your Profits: Discover how efficient adhesive spray coating can lead to significant cost savings and improved ROI.

-

Precision Matters: Learn how even a slight variation in adhesive thickness can impact your bottom line and find out how to optimize it for maximum cost-effectiveness.

-

Efficiency Unleashed: Explore the potential of increasing transfer efficiency by just 5% and see how it can result in substantial material savings of up to $300,000 annually.

-

Practical Solutions: Find out how adjustable controls for spray guns and a consistent spray booth setup can help mitigate wastage, ensuring your resources are used efficiently.

-

Validation and Proof: Understand how to validate your savings by accurately measuring adhesive usage, providing concrete evidence of the benefits of optimization.

-

Expert Guidance: Connect with us to receive tailored insights into your potential cost savings and take a step towards enhancing your business's efficiency and profitability.

Maximize Efficiency, Minimize Costs:

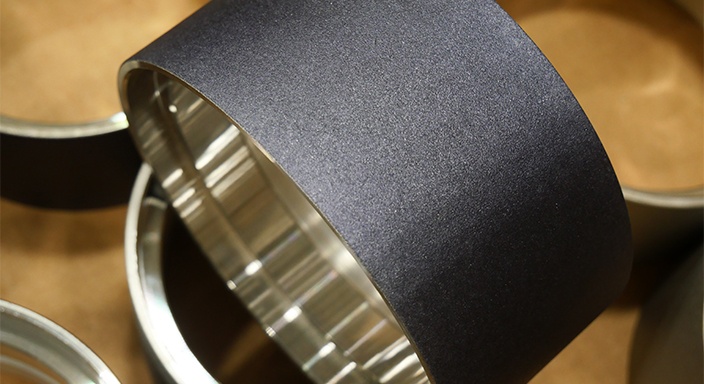

Adhesive application is a key step before rubber-to-metal bonding. Quality matters, but so does cost. By getting the adhesive thickness just right, you could save up to $780,000 annually. Even a tiny difference of 0.2 mils in primer and topcoat thickness, spread across 6 million parts, adds up.

Boost ROI, Improve Resource Utilization:

Standard spray methods often waste materials, with just 10-30% transfer efficiency. But here's the game-changer: every 5% increase in efficiency can save you around $300,000 a year. Picture the impact of efficient spraying on 6 million parts, at just $0.05 saved per part.

Solutions that Make Sense:

Mis-adjustments lead to waste. Combat this with adjustable controls for spray guns, controlling pressure and fluid settings. Combine this with a consistent spray booth setup for maximum efficiency. By cutting down on waste, you're increasing your profits.

Proven Validation:

We've done the math. To validate the savings, we've measured adhesive use. By comparing the surface area requiring coverage to a spray cycle into a graduated cylinder or comparing sprayed material weight to the overall coated weight of the part, you can see how much adhesive you're using. It's all about understanding where your money goes.

Reach Out for Success:

In the fast-paced automotive industry, optimizing your adhesive spray application isn't just a quality move – it's a smart financial move. With efficient coating, you're not only saving materials, you're driving up your ROI. Get in touch today and take the lead in efficiency and profitability.

Want to know your exact savings? With our expertise, you'll get a clear picture of how optimizing your adhesive spray application can mean big returns for your automotive business.