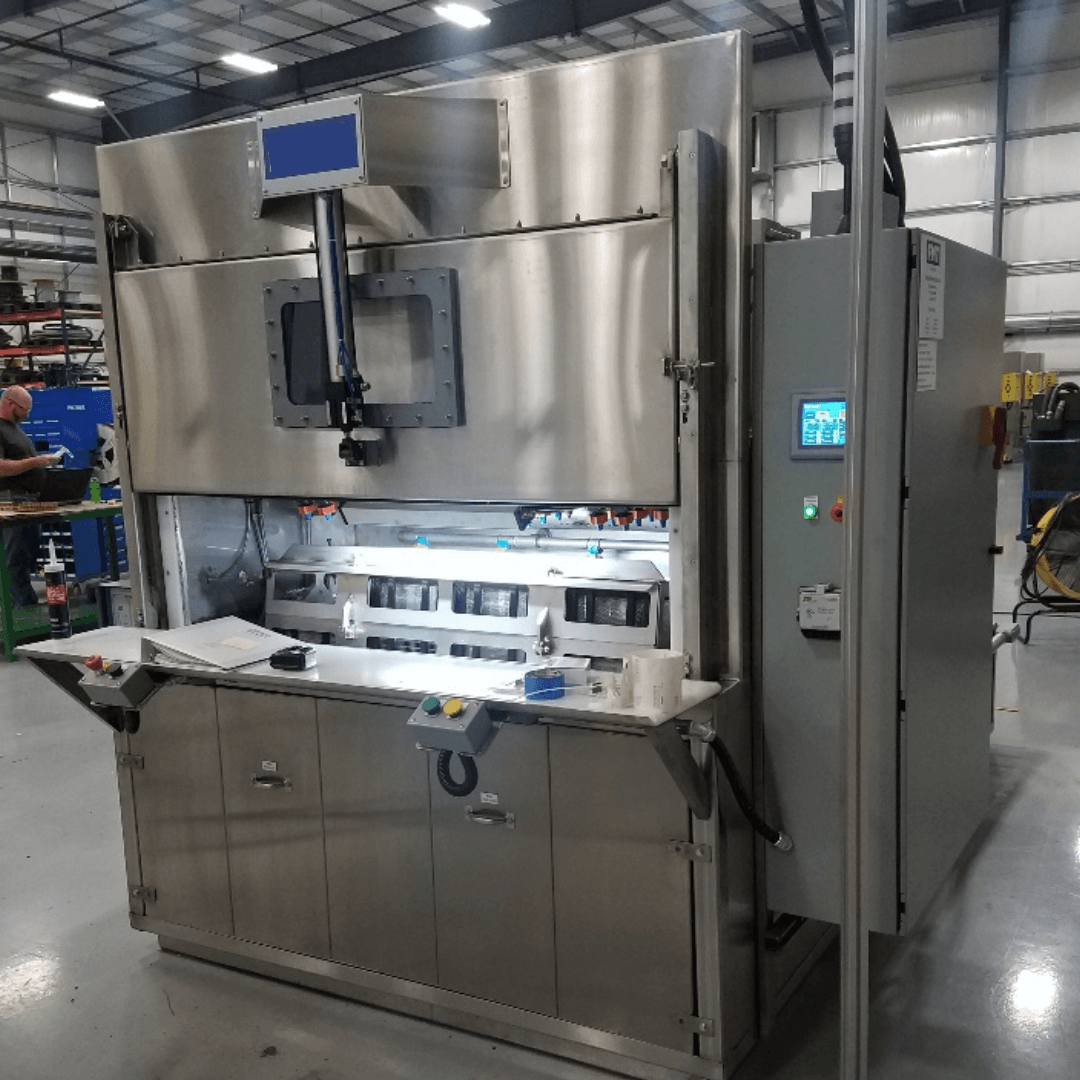

8RB50 Parts Washers

The 8RB50 Parts Washer is a Rotary Basket Washer designed for high-volume manufacturers dealing with small parts. It allows you to meet and exceed your cleanliness specifications with an increased capacity.

We custom-design your 8RB50 to ensure it’s tailored to your facility’s layout and your application’s unique requirements.

Benefits of 8RB50 Parts Washers

✔

Ultra-High Cleanliness Levels

Exceed the cleanliness requirements of your parts. Ultrasonics are available for high-precision applications.

✔

High-Volume Washing

Increase your current washing capacity to meet or expand your high-volume production rate.

✔

Fully Customizable

Wash your parts with a machine that is custom-designed for your facility and unique parts-washing requirements.

How 8RB50 Parts Washers Work

8RB50 Parts Washers can wash 8 baskets of parts at a time, typically in a four-over-four configuration. A typical wash cycle is heated wash > heated rinse > heated dry.

For precision-clean applications, Arnold Machine can add an ultrasonic bath into the wash cycle. We can also configure your machine to have additional rinse cycles, including fresh water rinses.

The time of a wash cycle will vary based on the requirements of your application. A common wash cycle is 12-15 minutes–in this application, 8 baskets of parts are completely clean and dry in just 15 minutes.

Common Applications

The 8RB50 Parts Washer is ideal for applications that involve small parts, parts that can fit into baskets that are roughly 15” long, 9” wide, and 4” tall.

This machine is used by manufacturers across a wide range of industries. It is particularly popular in the automotive industry for parts such as brake components, transmission components, and other small automotive parts.

Specs & Features

- You have the option to change the time and temperature for wash/rinse and dry-off cycles via the HMI at any time

- Optional chemical monitoring and chemical addition are available

- Ultrasonics can be added for “ultra-cleaning” purposes

- Baskets that hold the parts being washed can:

- Hold bulk parts that can tumble against one another

- Be compartmentalized to hold parts individually to prevent damage to sensitive parts

- We can integrate an oil coalescer to prolong the life of the wash solution

- We can implement a freshwater rinse after the wash stage or rinse stage

- Arnold Machine proudly supports all of our parts washers through our dedicated Ohio service team and can send out technicians to your location to perform troubleshooting and repairs

Arnold Machine acquired FMT in July 2020, and Arnold Machine’s extensive automation experience, combined with FMT’s industrial parts washer expertise, allows us to offer unique automation capabilities to parts washers. Our products include features such as material handling and automated (or robotic) loading and unloading.

Trust Arnold Machine with Your Parts Washing Needs

Are you looking to improve your current parts-washing process? Arnold Machine specializes in designing and manufacturing custom parts washers tailored to your needs and requirements. We ensure that your equipment will meet the highest cleanliness standards and provide efficiency and durability. Contact us today to get a quote and discover how we can optimize your parts-washing process.

8RB50 Parts Washer FAQ

-

Will the 8RB50 fit in our available space?

-

How often will I need to drain and clean the tank?

-

What does the Arnold Machine 8RB50 custom parts washer cost?

See our resources—or case studies below—to help you in the research process.

FEATURED POSTS

8RB50 Parts Washer: A Solution for Construction Manufacturers

Learn how a custom-designed 8RB50 Parts Washer helped a heavy-duty construction equipment manufacturer improve its corporate cleaning.

3-Stage Rotary Basket Washer Increases Capacity

Learn how a 3-Stage Rotary Basket Washer helped a major supplier of metal stampings meet its cleaning needs with increased capacity.

What is a Fully-Automated Rotary Basket Parts Washer?

Learn about the features and benefits of fully-automated Rotary Basket Parts Washers and their advantages over manual cleaning processes.