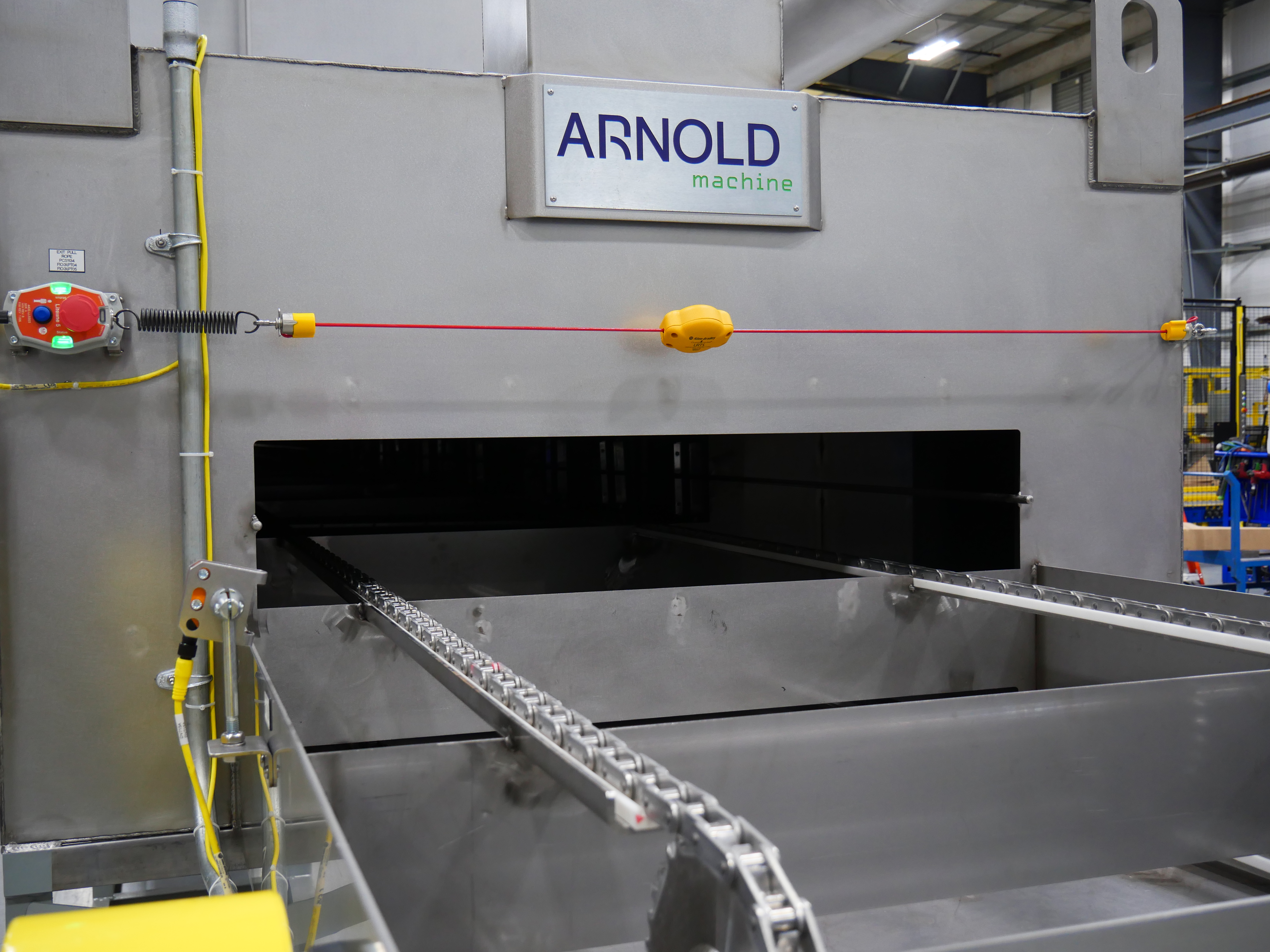

PARALLEL CHAIN CONVEYOR PARTS WASHERS

Parallel Chain Conveyor Parts Washers from Arnold Machine deliver precision cleaning for diverse industrial applications. We customize our versatile washers to handle parts of any size or shape—from delicate components to heavy engine blocks.

The parallel chain design allows secure part fixturing for targeted spray patterns and consistent results every time. These washers are ideal for automated production environments with robotic loading and indexing capabilities.

We build each washer using top-of-the-line industrial-grade components to ensure exceptional durability. Our skilled fabrication team crafts every machine with meticulous attention to detail while expert service technicians provide comprehensive installation and training.

BENEFITS OF PARALLEL CHAIN CONVEYOR PARTS WASHERS

HOW PARALLEL CHAIN CONVEYOR PARTS WASHERS WORK

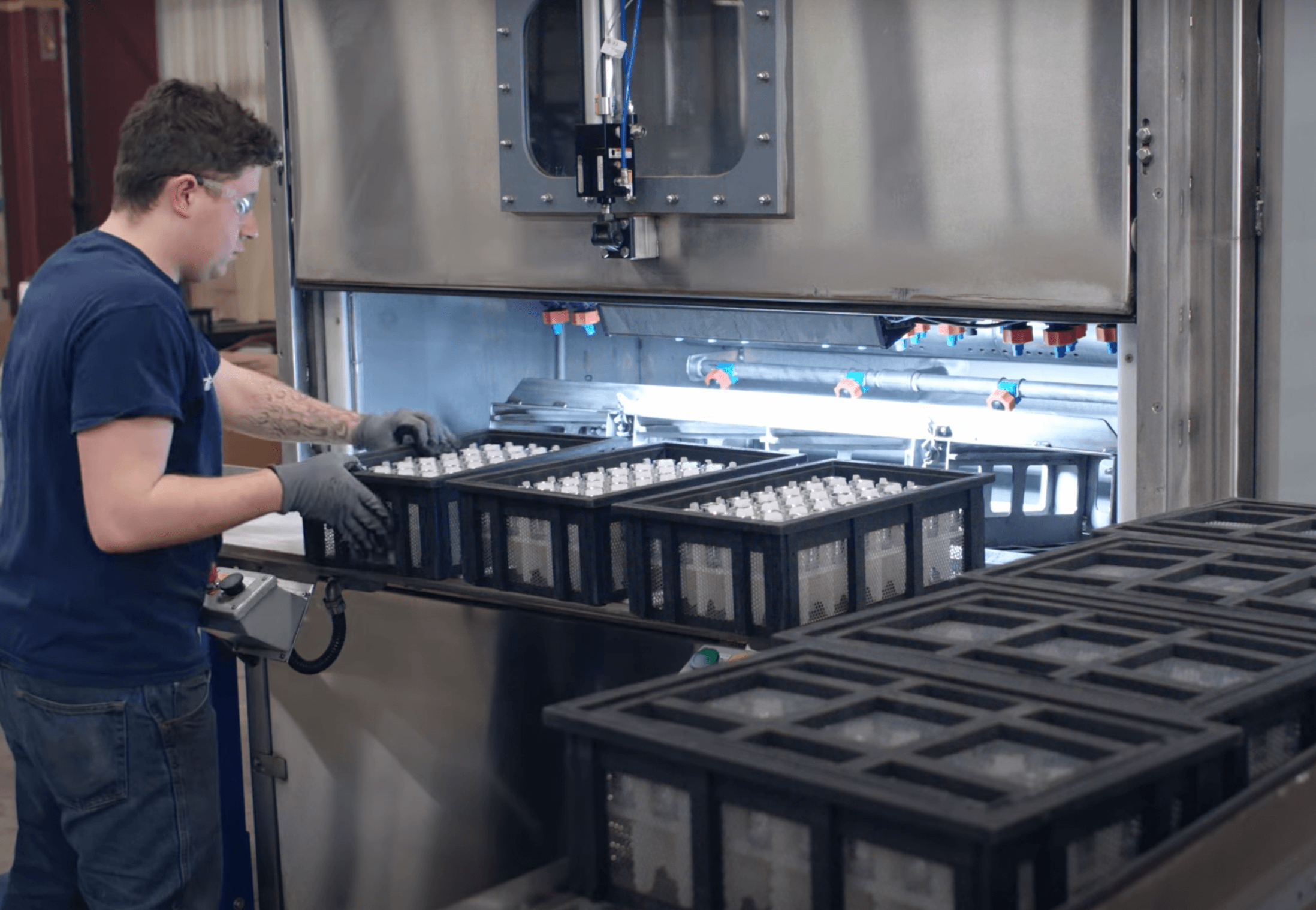

These innovative parts washers use a parallel chain system to securely fixture parts as they move through multiple cleaning stages. The chains can be customized for continuously moving or indexing based on part shape, size, volume, and available space in your facility. Most systems include a wash stage, rinse stage, and blow-off stage, with options to add more stages if needed for thorough cleaning.

The parallel chain design allows precise positioning of spray nozzles to target specific areas on each part, ensuring consistent results even with complex surfaces. Parts are typically loaded and unloaded manually, but robotic or automatic feed systems are also available to streamline the process. This flexibility makes Parallel Chain Conveyor Parts Washers an excellent solution for diverse industrial cleaning applications.

COMMON APPLICATIONS

Parallel chain pass-through parts washers are ideal for high-volume cleaning applications where precise targeting of specific part areas is required.

These machines can handle virtually any type of part, but they excel at washing large items like pallets and bins that need to be securely fixtured in a jig during the process.

The parallel chain design enables focused spray patterns and consistent results even with complex or hard-to-reach surfaces on each part.

SPECS & FEATURES

We design our Parallel Chain Conveyor Parts Washers with a range of features for efficiency and ease of use. Our washers are built to meet various customer needs and preferences. Here are some key specs and features:

- Automatic level control for consistent performance

- Chemical monitoring and addition systems

- High-pressure spray for thorough cleaning

- Heated or ambient wash and rinse options

- Heated or ambient blow-off to dry parts effectively

- Temperature and pressure monitoring for safety

- Quick-disconnect spray headers for easy maintenance

- Gull-wing style doors for convenient access

- Additional features are available upon customer request

- Drain pump-out tank for efficient waste management

- Filter bag replacement while running to minimize downtime

- Cross-contamination prevention measures

- Adjustable belt speeds to suit different parts

- Mist collection or exterior exhausting options

- Customizable Operator Interface (HMI) to meet user preferences

TRUST ARNOLD MACHINE WITH YOUR PARTS WASHING NEEDS

At Arnold Machine, we understand the importance of efficient and reliable parts washing for your operations. Our custom-designed washers are built to meet your specific needs and exceed precise cleanliness standards. We prioritize durability and efficiency in every machine we manufacture. Contact us today to get a quote and learn how our solutions can enhance your parts-washing process.

PARALLEL CHAIN CONVEYOR PARTS WASHER FAQ

-

What spare parts do you recommend?

-

What type of cleaning solution and concentration do you recommend?

-

Can you accommodate the size of our parts and the volume of parts we need to wash per hour?

FEATURED POSTS

6 Most Common Problems with Washing Parts

Industrial parts washers often encounter issues such as non-starts and incomplete drying. Fortunately, most of these problems can be resolved in-house through effective troubleshooting.

Parts Cleaning Equipment Designed for the End User

Arnold Machine parts washers improve cleanliness, boost safety, and reduce labor needs. Learn how our customer-focused approach delivers reliable equipment tailored to your needs.

What is a Fully Automated Rotary Basket Parts Washer?

Due to their labor-intensive nature, manual parts washers struggle to keep up with evolving production needs. Fully automated rotary basket parts washers offer a viable and efficient solution.