Automating Anti-Vibration Component Assembly: A Guide for Automotive Manufacturers

Anti-vibration mounts are crucial to ensuring safe and comfortable automobile travel. They reduce the risk of damage to mechanical and structural systems, quiet the noise resulting from parts in constant motion, and eliminate passenger discomfort associated with intense vibration.

This guide is designed for automotive manufacturers seeking to meet their customers’ stringent requirements while maintaining control over labor and supply costs.

What we’ll discuss:

- PART 1: How automating the rubber-to-metal bonding process sets the stage for more successful final assembly of anti-vibration mounts.

- PART 2: Two methods for automating final assembly of hydro mounts—dry-fill and under-fluid.

- PART 3: Why your on-site support team is necessary to achieve optimal performance of your automated system.

Part 1: Automating Rubber-to-Metal Bonding

Anti-vibration mounts are worthless if they do not properly adhere to the metal components connecting them to a chassis.

That’s why the rubber-to-metal bonding process requires precision and care. And while human workers are certainly capable of precise work, they’re not perfect. Profitable automotive manufacturing depends on turning out high-quality parts very quickly. Increasingly, human labor is more of a liability than an asset in these scenarios.

Incorporating a custom-automated machine guarantees quality at high volume. In addition, when the rubber-to-metal bonding process is less reliant on human operation, scrap rates and rework are reduced, and material costs are kept under control.

Automated adhesive spray systems are a key component of these machines. Adhesives typically range from $50 to $100 per gallon. Depending on process parameters, precise automated delivery of adhesive can generate a 50 – 75% savings.

Ensuring Safety in Automated Rubber-to-Metal Bonding

Safety is always a prominent concern for manufacturers. Adhesives are extremely flammable and contain volatile organic compounds (VOCs) that are hazardous to your team members on the manufacturing floor. Proper material handling and exhaust infrastructure are paramount.

Automated spray machines from Arnold Machine are explosion-proof and include fire suppression capabilities. Additionally, all machines properly exhaust volatile fumes by controlling the air flow and venting them safely out of the facility.

Part 2: Methods for Automating Mount Assembly

Mount designs vary based on their application. Some are solid molded rubber, so manufacturing stops after the rubber is bonded to metal assemblies. Others are made of hollow rubber filled with fluid, usually glycol.

In the case studies that follow, we discuss two different scenarios where our team developed automated manufacturing systems for glycol-filled mounts. The case studies explain how we helped major automotive suppliers meet their unique challenges head-on.

Case Study 1: Automated Dry-Fill Mount Assembly

The problem: Too-slow production and too many machines

Our customer contacted us about developing an automated assembly system for an engine mount for a major automobile manufacturer. The idea was to create a mount filled with fluid—a hydraulic engine mount.

The customer’s goal was multi-fold: Remove the human element, limit the number of machines required to assemble the components, and increase the overall production rate.

The solution: An automated 5-in-1 assembly system

There were a few challenges along the way. The first was creating an entirely new, multi-phase process featuring assembly and verification stages. At the time we built the equipment, no such machine addressing all these requirements had ever been developed.

Another challenge was manufacturing the interior of the engine mount. The fluid passageways within the interior of the engine mount are particularly complex.

Inside the mount, the orifice assembly—made up of a plastic body, rubber membrane, and steel plate—had to be staked via hot air cold stake before placement within the engine mount. We had to create custom tooling because the stake pins for the process were so close together.

Additionally, there are five different components requiring assembly before the part is filled. Our engineering team had to sort out how to fit each process within a single machine. The components of the part had to be swaged down before they could be assembled. The swaging process had to be built into the machine to not only fit parts within one another but also seal up the mount before adding fluid.

Lastly, when air is vacuumed out of the mount and fluid is injected in its place, any amount of leftover air will result in a failed inspection. A tremendous amount of research and development went into ensuring the removal of all the air and the subsequent replacement with fluid within the required cycle time. To complete this, our engineers invented a 3-way valve that engages the engine mount and shifts from vacuum to fill within the cycle without ever disengaging from the part and without letting any air in.

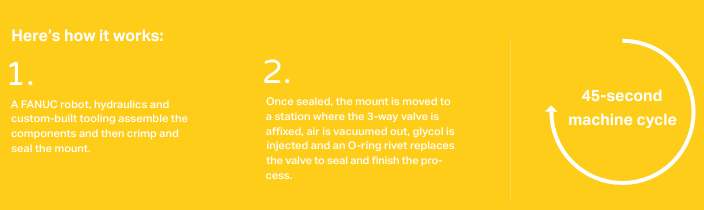

The result: Increased production rates with less human error

Arnold Machine built the assembly machine using laser cutting, CNC forming, welding, CNC milling, and turning. The machine utilizes a FANUC robot, hydraulics, and custom-built tooling to assemble the components and then crimp and seal the mount. Once sealed, the mount is moved to a station where the 3-way valve is affixed, air is vacuumed out, glycol is injected, and an O-ring rivet replaces the valve to seal and finish the process. The total machine cycle time is less than 45 seconds. The result is a single machine that removed the human element from difficult-to-verify processes and provided an increase in production rate while maintaining consistency and accuracy.

Case Study 2: Automated Under-Fluid Mount Assembly

The problem: Inconsistent cycle times and too much scrap

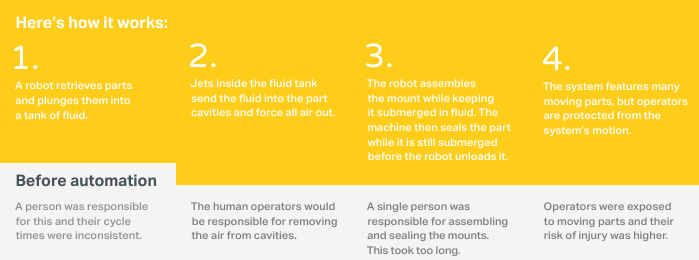

In this instance, a major North American automotive supplier realized it needed to rethink how it mass-produced hydraulic engine mounts. Before integrating the system we built, the customer relied on a manual assembly and filling process. This setup was prone to some inconsistencies.

For one thing, the customer could not guarantee that each engine mount would be assembled the same way every time. Such is the nature of having people who are not perfect on the job.

For another, the consistent and correct filling of the mounts with fluid also could not be guaranteed. The mounts are specified to be totally full without any air pockets. But they’re only tested after being sealed. By that point, rework is impossible. Mounts that failed the test had to be rejected.

Add to these issues the fact that human workers cannot do repetitive tasks at the same pace from the beginning to the end of their shifts. Cycle times were unpredictable, and too many mounts had to be rejected because they were assembled incorrectly, were not full, or both.

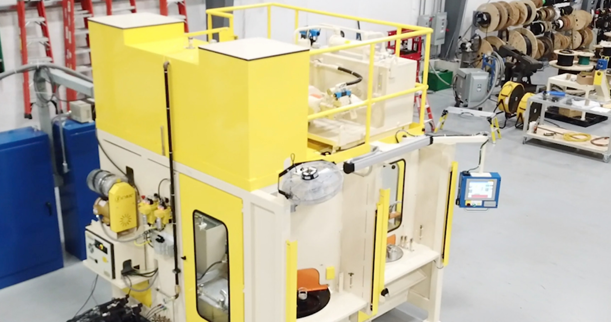

The solution: Automated under-fluid assembly to guarantee quality and decrease cycle time

Arnold Machine had successfully delivered many automation solutions to this customer in the past. That existing relationship led the customer to call on us again. Our task was to develop a system that eliminated inconsistency and improved the cycle time of the assembly and filling process.

Our idea was to assemble the components robotically inside a tank of fluid. The robot carrying out these tasks was a FANUC LR Mate series system. LR Mate models are highly customizable, with reaches ranging from 550 mm to 919 mm on a five- or six-axis format, depending on process requirements.

The LR Mate models are also compact and lightweight, making them perfect for the small footprint of the machine we built. Because of that, no facility or workflow modifications needed to be made in our customer’s plant to accommodate this automated system.

The result: Stabilized, speedy assembly minus scrap and human error

Thanks to our work, production of hydraulic engine mounts in the customer’s facility stabilized. Scrap rates were significantly reduced, and cycle times were cut in half, dramatically increasing throughput.

This automated solution has worked so well that the customer has continually ordered more of these systems.

This customer’s integration of our automated hydraulic mount assembly system has made them a preferred supplier to automotive OEMs. Because they can guarantee higher quality at a competitive price, their business has improved.

Part 3: On-Site Support: The Foundation of Successful Automation

The success stories we featured above highlight customer triumphs thanks to the equipment we built. But it’s important to note that better quality, increased volume, and reduced waste don’t happen at the flip of a switch.

Full utilization of a custom automated system has a greater chance of success with support personnel around it.

While our team completes the fine-tuning, including simulating as many scenarios as possible before your system is ready for its debut, the ongoing support your team provides is the ticket to achieving the best results.

The Role of Your On-Site Support Team

Whether you’re new to automation or have integrated automated systems before, getting a new system online is a major task. Our advice is the same for those very familiar with automation and those new to it: Have people in place capable of supporting your automated equipment at all times.

They’ll hit the ground running from the moment your machine arrives. As we stated above, our team completes the initial setup and testing of the machine. We then prepare the machine for safe shipment and meet it at your facility to assist with installation. For the greatest understanding of the automated system, it is advised that your internal support team is involved in the reassembly and startup at your facility.

Once our teams complete installation, more testing and validation must be completed prior to our team leaving. This is when your team begins to run the machine as it will run in production, with Arnold Machine present to ensure the equipment will perform according to your requirements. Once the on-site validation is complete, we leave the system in the hands of your on-site support team.

Having a support team on staff enables you to perform basic troubleshooting as new scenarios arise in the production environment. We try to plan for everything at Arnold Machine, but some instances arise on the production floor that we cannot plan for. If this happens, a skilled support staff can be the difference between hitting production numbers that shift or not.

We’ll Help Put Your Support Capability in Place

An in-house support team is a critical element when automating your production facility. Since this may be a new venture for our customers, we would like to discuss it while the project is in its early stages. Ask yourself whether your team is ready to support automated equipment. If it’s not, Arnold Machine is ready to help.

We’re proud integration partners of FANUC and Rockwell Automation. Through these partnerships, our engineering and technical support staff are kept up to date on the latest technological advancements in automation. This also allows Arnold Machine to offer our customers training programs through FANUC or Rockwell Automation, ensuring they have the resources they need to be successful.

With this groundwork complete, you’re in a position to get the most out of your automated system and are equipped to handle any challenges that arise quickly and efficiently.

Quick Tips:

- For added peace of mind, Arnold Machine is always available for assistance. We can even monitor your system from our office. With your permission, we can log in from our office, identify an issue, and help your team resolve it virtually. We recommend this technology for every system and are happy to discuss it in more detail.

- Keeping an inventory of replacements for high-wear and long-lead time parts is critical to minimizing machine downtime. Our team will assemble a list of recommended spare parts with the engineering package so that you can react quickly to outages caused by part maintenance or replacement needs.

Are You Ready to Thrive?

By choosing to automate anti-vibration mount assembly, labor costs are optimized while quality and efficiency are enhanced. It’s a major investment in your company’s future.

By developing innovative automated anti-vibration equipment and empowering your on-site support team, Arnold Machine, Inc. helps you make sure your future is as bright as possible.

Are you preparing to automate a process in your facility? Let’s talk about it.