ACHIEVING SPRAY COATING PRECISION THROUGH GREAT PARTNERSHIPS

Arnold Machine is the industry leader in automated spray coating technology. Our systems combine precise controls with advanced equipment to deliver consistent results in manufacturing applications.

We attribute part of our success to strategic partnerships with innovators like Parker Lord and Krautzberger. This collaboration gives us access to best-in-class adhesive materials and precision spray equipment technologies.

Read on to learn more about how our engineering expertise and industry collaborators can help achieve precise spray coating for your parts.

ARNOLD MACHINE COATING SYSTEMS

At Arnold Machine, we engineer custom robotic spray coating systems for industrial applications. Our automated solutions deliver uniform coverage to minimize material waste on every manufactured part. Intelligent recipe-based controls maintain precise production specifications for consistent quality.

Advanced spray booths protect workers with sophisticated airflow management and VOC exposure control. Our flexible systems handle both batch and continuous processing operations with streamlined maintenance procedures. They maximize production uptime through integrated monitoring and rapid parts replacement.

We manufacture the following systems:

- Chain-on-Edge Conveyors - Innovative conveyor design revolutionizes production lines by optimizing material flow. Advanced automation technologies reduce labor costs while maximizing throughput efficiency.

- Tumble Spray Coating Systems - Precision tumbling mechanisms ensure flawless 360-degree coverage for complex part geometries. Smart spray pattern controls eliminate manual labor requirements while maintaining coating consistency.

- Roll Coater Systems - State-of-the-art roller technology provides superior finish quality through uniform material application. Modern integration features adapt seamlessly to existing production lines while preserving precise coating thickness.

- Interior Diameter (ID) Tube Spray Machines - Dynamic spray heads optimize internal coating processes for superior surface quality. Intelligent stroke control upholds strict safety protocols while delivering consistent coverage.

- Automatic Viscosity Bulk Mixing Stations - Continuous monitoring systems maintain precise material viscosity through real-time adjustments. Automated mixing controls ensure consistent coating quality while eliminating manual intervention.

The Importance of Spray Coating Efficiency

Spray coating is a critical part of manufacturing. Traditional methods waste a lot of material, with only 10-30% of the coating actually sticking to the surface. Even a small improvement can lead to big savings.

For example, a 5% boost could save around $300,000 each year for a company producing 6 million parts. These savings show how focusing on better methods can cut costs and improve profits.

Improving spray coating also helps manufacturers work faster and smarter. Companies can find ways to upgrade equipment, train workers, and streamline workflows by analyzing current processes. Investing in new technologies and exploring better coating methods can reduce waste and eliminate bottlenecks. These changes help lower costs and make production more efficient and sustainable in the long run.

PARTNERSHIP WITH PARKER LORD

Parker Lord manufactures specialized adhesives for Arnold Machine's coating systems. These adhesives form strong rubber-to-metal bonds in automotive and industrial applications. We’ve worked closely with them to ensure these formulations can be optimized with our automated spray-coating machines.

The collaboration enhanced our systems in several ways. Parker’s deep understanding of adhesive properties helped us develop better viscosity controls. Their expert guidance shaped our spray patterns to ensure proper coverage. The technical insights they provided influenced our method for maintaining consistent coating thickness.

Parker Lord’s advanced adhesives play a critical role in our coating process. The unique formulations allow our automated systems to deliver exact coating thickness. Our viscosity controls adjust these materials in real-time for optimal performance, achieving repeatable quality across every production run.

PARTNERSHIP WITH KRAUTZBERGER

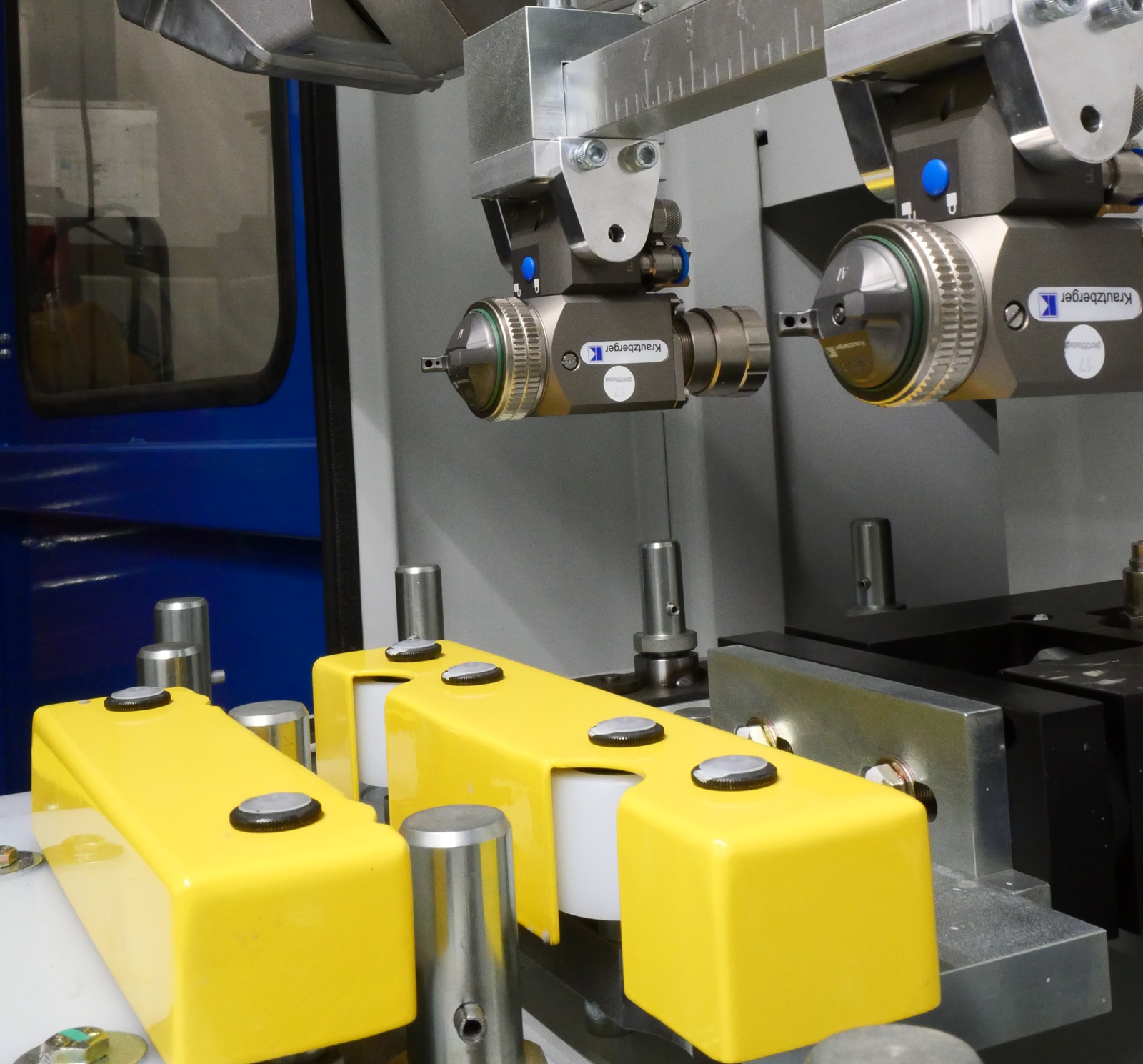

Arnold Machine has also partnered with Krautzberger, a company that has been improving spray gun technology for over 100 years. This partnership lets us focus on material handling and process control within our coating systems. We rely on Krautzberger's expertise to provide the best spray gun for each coating material that needs to be applied.

Krautzberger provides the spray guns for Arnold Machine's coating systems. They also can manufacture custom spray gun extensions for non-standard applications. This critical partnership aspect allows us to offer tailored solutions for our customers' unique needs.

The spray guns and fluid controls from Krautzberger play a vital role in Arnold Machine's coating systems. They ensure that the coating material is applied efficiently and precisely. Combining Krautzberger's spray technology with Arnold Machine's expertise in process automation helps customers get the best results. The result is a custom-built machine that can handle any spray application.

PROVEN SOLUTIONS FOR COMPLEX COATING CHALLENGES

Strategic partnerships with industry leaders Parker Lord and Krautzberger strengthen Arnold Machine’s position as the automated coating system industry expert. Decades of combined experience in adhesives, spray technology, and automation allow us to develop precise coating solutions for complex manufacturing challenges.

Click below to explore the advantages of our automated coating solutions.