WHAT IS A FULLY AUTOMATED ROTARY BASKET PARTS WASHER?

Manual parts washers provide a wide range of benefits to any manufacturing production line. However, they are labor-intensive and cannot scale with evolving production demands. Given these limitations, engineering managers need a more optimized solution.

Fully automated rotary basket parts washers perfectly fit this need. These innovative machines automatically load and unload parts with minimal oversight. This streamlined process boosts efficiency, reduces costs, and decreases labor requirements.

Read on to learn how implementing a fully automated rotary basket parts washer will transform your parts-washing workflows.

UNDERSTANDING ROTARY BASKET PARTS WASHERS

Rotary basket washers efficiently accommodate various parts in batch cleaning processes. The standard or specially designed baskets and fixtures allow operators to load and wash parts of all sizes and geometries.

These heavy-duty washers are ideal for spray, partial or full immersion, and ultrasonic cleaning requirements. Standard rotary basket washers come in capacities of 2, 4, 6, or 8 baskets and manual or automatic loading/unloading systems.

Arnold Machine rotary basket washers offer a wide range of valuable options, including multi-stage washing, rust inhibitors, and specialized filtration. This flexibility allows us to configure a washer to align with your needs and processes.

MANUAL VS. AUTOMATED WASHERS

There are two primary varieties of rotary basket washers. Manual models that require hands-on labor and automated options that dramatically reduce human involvement. While both systems effectively clean parts, automatic washers streamline operations through programmed loading, washing, and unloading cycles.

Manual washers require operators to load parts into fixtures or baskets and then rotate 180 degrees for the next set of parts. At cycle completion, they need to unload each basket. This tedious process requires workers to invest significant time and labor.

For example, a typical 4-basket manual washer means workers may spend 15-20 minutes loading parts before a wash cycle can begin. Unloading takes just as long. A single wash cycle can take upwards of 40 minutes of total labor. This hands-on process also leaves room for potential scratches or part damage from excessive handling.

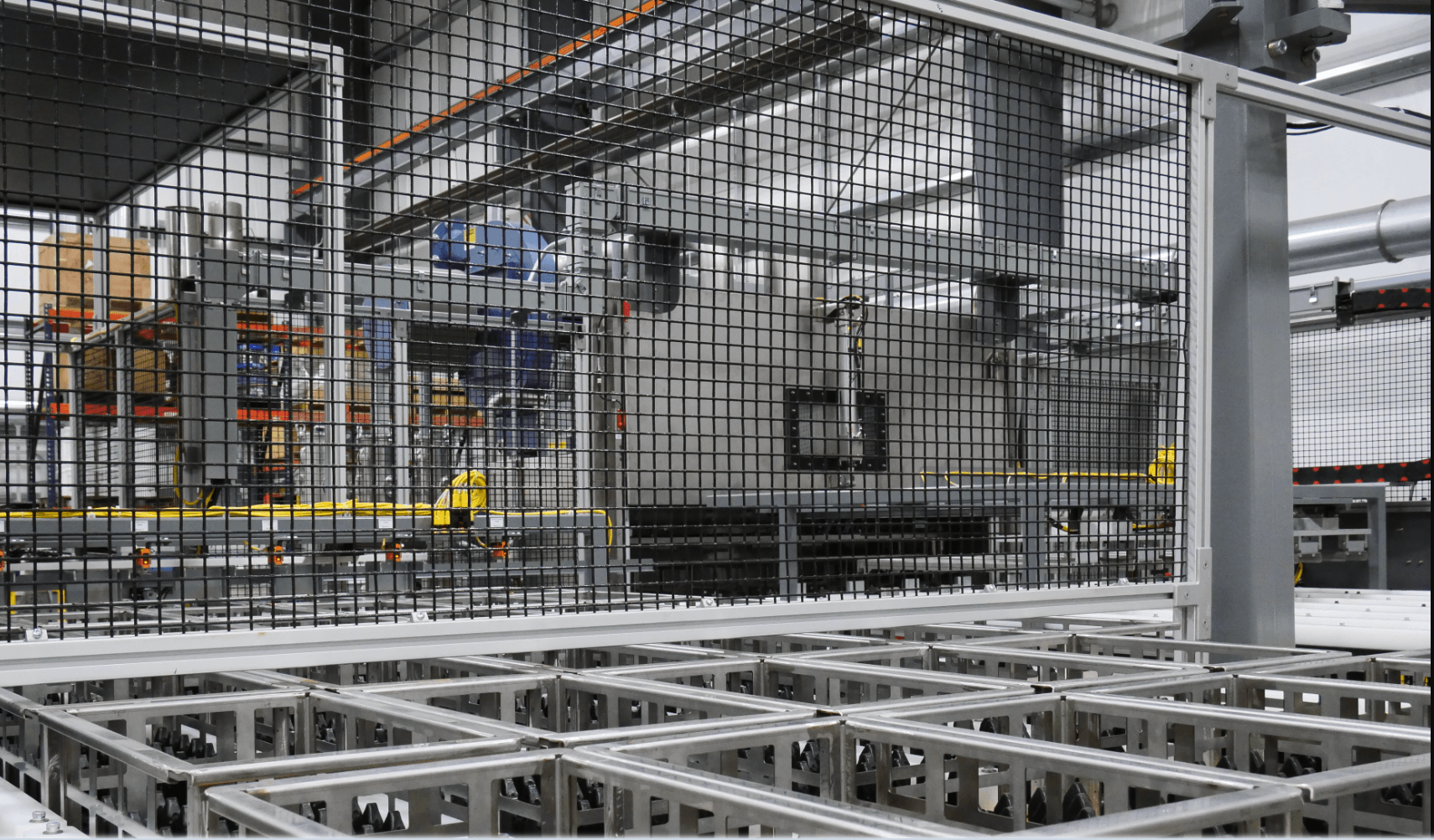

In contrast, an automatic rotary basket washer minimizes human labor drastically. They’re ideal for manufacturers looking to automate their production lines. Conveyors and optional integrated robots efficiently handle parts loading and unloading with little worker oversight. Minimal direct handling limits the risk of damage as parts undergo the washing process.

Management can allocate workers to more value-added tasks rather than investing labor in parts loading/unloading. Eliminating these manual steps can save 50% or more labor costs than a manual washer operation.

With programmable cycle controls, automated washers also promote consistency and optimize cycle times, which average 15 minutes. Overall, the precision and efficiency delivered by automation take rotary basket parts washing to the next level.

FULLY AUTOMATED SYSTEM FEATURES

Fully automated rotary basket washers from Arnold Machine incorporate innovative features such as programmable logic controls, automated loading/unloading conveyors, and optional robotic technologies. The worker only needs to load the baskets onto the infeed conveyor.

Standard features include single-stage and multi-stage wash systems, precision spray nozzles, soundproofing, leak-free welded joints, and robust drive systems. Options like custom part fixturing, high-pressure spray options, and specialized filtration create a parts washer tailored to your process specifications.

BENEFITS OF FULL AUTOMATION

The precision and consistency achieved by automated rotary basket washers offer a significant advantage over manual washers. Automated systems ensure that cleaned parts reliably meet quality control standards by minimizing variability in the cleaning process. This prevents defects and avoids potential waste from rewashing.

Fully automated loading and unloading also minimizes direct labor costs associated with parts processing. Automating the system for a 4-basket parts washer operating two shifts per day can save significant labor costs. Optimized cycle times averaging 15 minutes also maximize throughput. These parts washers can increase production by 20% or more compared to manual ones.

Automated rotary basket washers deliver tremendous cost and time savings while adhering to the strictest clean and dry specifications. The capital investment in automation technologies pays dividends through increased productivity, reduced labor expenses, and consistently cleaned parts.

ARNOLD MACHINE'S EXPERTISE IN ROTARY BASKET PARTS WASHERS

With nearly 35 years of experience, Arnold Machine leads the industry in building high-quality customized rotary basket washers. Our team crafts durable washers using heavy-gauge 304 stainless steel, precision spray nozzles, and premium components.

We thoroughly assess each client's parts, production goals, and parameters. We then design a fully automated washer tailored to maximize efficiency and quality. Custom programming optimizes PLC cycle controls. Strategic basket and fixture design effectively cleans all geometries.

Options like multistage washing, specialized magnetic filtration, and robotics integration showcase our innovative capabilities. Our engineered solutions solve complex washing challenges and deliver productivity gains.

We provide unmatched expertise from consultation to installation and beyond. Maintenance training and robust washer construction ensure maximum uptime. Clients gain a customized system built to boost production with our automated rotary basket washers.

PRECISION PARTS CLEANING PERFECTED WITH AUTOMATED WASHERS

Automated rotary basket parts washers deliver transformative efficiency and precision to batch parts cleaning. Arnold Machine will design the ideal automatic washer to solve your toughest parts washing challenges. Click below to explore our industry-leading rotary basket washers.