Automatic vs. Manual Spray Systems

When it comes to industrial coating systems, manufacturers have two primary options: manual or automated. This article compares both approaches, highlighting the benefits and limitations of each and exploring how automation can improve consistency, reduce waste, and lower long-term costs, especially in high-volume production environments.

Benefits of Automating Spray Processes

Automating spray processes offers a range of advantages that go beyond precision and speed. From reducing material waste to improving overall efficiency, automation can deliver significant cost savings and cleaner operations.

Cut Waste and Save on Material Costs

Automated systems will spray a consistent amount of paint where and when it is required. Consistent and repeated spraying means less paint is sprayed overall. Spraying less paint saves money, which means less maintenance and cleanup. It also lowers filter costs and VOC emissions.

Automated systems can bring consistency and efficiency, resulting in both direct and indirect savings. Arnold Machine specializes in providing off-the-shelf and customized automated spraying systems. By working with customers to achieve their desired goals, we can provide the proper system to optimize key processes in an automated system.

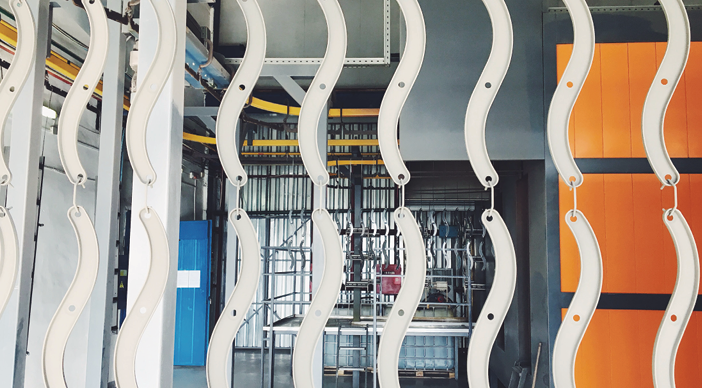

One of our clients, an automotive component manufacturer, reported over $300,000 in material savings after switching to an automated Chain-on-Edge Machine.

Manual Spray Processes

For low-volume products, maintaining consistent part fixturing might not be cost-effective. In this case, an operator's eyes, brain, and hands will work together to correct for variations in the positioning and compensate.

When a part is slightly askew, the operator will compensate for the problem by redirecting the paint appropriately. On the other hand, automated systems are basically “blind,” they must assume the parts are oriented in a specific and consistent way.

Since it approaches each part with the same painting commands, any improperly fixtured parts will not be painted properly. Manual operators are better able to handle unexpected situations where hangers might sway or parts are poorly racked. In most cases, an operator can be as precise as a robot, but the repeatability of the end product can be affected.

These include personal vision, alertness, flexibility, and even their mood from day to day. In the manual spraying processes are more cost-effective at running low volume production, but their effectiveness is eclipsed as volumes increase.

Automatic vs. Manual

In production manufacturing, there are several ways to spray a part. From the basic continuous motion Chain-On-Edge machine, spraying parts as they pass, to the more advanced robotic spray machines, individually spraying complex parts with a single arm.

In the past, the spraying was done manually with an operator holding and controlling the direction of the spray gun and spray. Although effective for smaller batches of parts, this process lends itself to variations in quality from part to part.

The key to developing a robust and repeatable process is to develop machines that reduce these process variations.

The first step in any automation plan is to identify how these variations are a part of the process. Keeping items such as paint viscosity, substrate temperature, air pressure, and the gun set-up consistent are primary areas that can benefit from automation.

Viscosity

Controlling viscosity is one of the most important parts of any coating process. The viscosity of the material is the fluid’s resistance to flow - the internal friction of the fluid. This characteristic directly affects the coating thickness and overall quality of the part.

Typically, sprayed materials are mixed by operators and checked for viscosity using a measuring device like a Zahn cup. However, the measured results from such devices can be arbitrary and vary from operator to operator.

Substrate Temperature

Substrate temperature during drying is another important part of the spraying process. The temperature of the substrate being coated directly affects the drying time and the coating thickness. A preheated substrate assists in achieving the target dry times. By controlling the temperature of the substrate, consistent, high film builds can be laid without runs in the coating.

Air Pressure Settings in Spray Guns

The air pressure setting of the spray gun is also a factor that often varies in a manual spray process. The air settings not only affect the quality of the part but also the amount of material used. Too little pressure and the paint is not properly atomized, while too great a pressure causes much of the paint spray to bounce off the substrate and be wasted.

Gun Setup of a Spray System

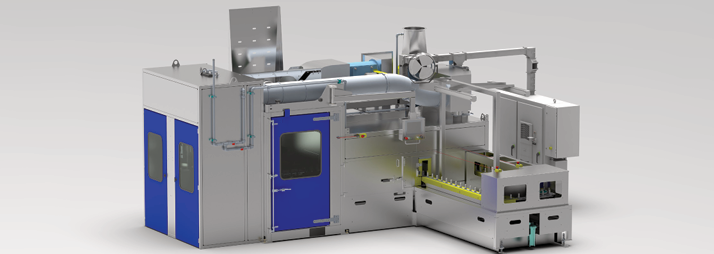

The gun setup of a spray system is one of the best areas for automation. Spray machines are designed to run several different setup operations, so having programmable gun positions reduces setup time and wasted material.

Spray guns can be programmed to run multiple processes on the same part or within the same production line. For more complex parts, robots can be used to move the gun during the spray processes to replicate coverage that previously could only be done by an operator.

Programming Options

One key to the repeatability of automating spray ing systems is their ability to run programs again and again. Programs can be set, altered, rechecked, and optimized. With programmable gun systems, this programming consists of simple spray or no-spray commands as the gun moves vertically, horizontally, or rotationally in front of the items. However, for most robotic systems, the programming becomes more complex with integrated path programming of six or more axes of motion.

Find the System That’s Right for You

The top reason for automating a spraying system is to eliminate labor costs. However, to believe that replacing operators with robotic automation will ALWAYS reduce costs is too simplistic. For small operators with a low volume of complex parts that might require hundreds of programs, the use of a robot may increase costs. Similarly, robots are often costly when compared to programmable gun solutions.

When replacing a $30,000 worker, three shifts a day, the cost of any gun setup automation can be quickly recuperated. However, there is a lot of automation that can be purchased for far less than the cost of a robot. It is important to investigate all possibilities before settling on the solution.

Regardless of what type of spray machine is being used (Indexing, Chain-on-Edge, Overhead Conveyor, Robotic, Tumble, Roll Coater, Pallet Transfer, or Tube ID Lance), Arnold Machine can integrate all of the automation options listed above to control the spray application process. The challenge to designing an automated machine is always how much automation you want to install in it. In most cases, reducing the variables with automation will allow for a consistent part quality and an efficient process to be achieved.

Contact us today for a quote!