Adhesive Spray Systems: 3 Examples of Automation Improving Production

Applying adhesive to parts during manufacturing is critical to the eventual end use of countless components and systems. As such, engineers recognize the need to streamline this important production stage while preserving quality and consistency.

And yet, many manufacturers rely on manual or semi-automated processes that are wasteful, unsafe, imprecise, or slow.

Custom-designed automated adhesive spray systems can offer manufacturers higher production rates, increased efficiency, lower costs, and improved worker safety. Read the three case studies below to learn about the improvements manufacturers have made after integrating custom automated systems from Arnold Machine, Inc.

Case Study #1: Automated Spray Adhesive System Increases Capacity 6x for a Global Oil & Gas Drilling Equipment Manufacturer

Many of the components used to extract oil and gas are used in harsh service environments. Drilling equipment is expensive and difficult to repair or replace in the field. That puts pressure on the firms that manufacture these critical assets to ensure they can stand up to abusive applications for years at a time.

Our client, a major global equipment manufacturer, was feeling that pressure. An existing process for applying adhesive to the inside diameter of down-hole tubes was slow, wasteful, and potentially dangerous to workers. They needed to reduce delays in manufacturing, increase production capacity, and eliminate worker safety hazards.

The Problems with an Imprecise & Wasteful Process

The down-hole tubes our client manufactures reach 25 feet long and can weigh up to two tons. The insides of the tubes must be coated in adhesive so that the rubber molded to the inside of the tube adheres to the metal.

Because adhesion of the rubber to the tube is so critical to the part’s end use, workers had to ensure the adhesive they applied to the tube achieved a consistent dry film thickness (DFT) of between one and two mils.

But the adhesive application method made it almost impossible to achieve consistent results. Here’s a rundown of the original process:

- Tube sections were hoisted up and then positioned at a 45-degree angle to the ground in a cradle.

- Workers climbed onto a mezzanine to access the high end of the tube and manually poured a base coat of adhesive into it.

- The tube was rotated during pouring to achieve more complete adhesive coverage.

- Next, the tube was left to dry in ambient air before the process was repeated for a topcoat.

Our customer wanted to overhaul the process for several reasons.

First, only around 50% of the adhesive poured down each tube stuck to its inner surface, and the rest dripped out the bottom. At $50 to $100 a gallon, the cost of wasted adhesive added up quickly.

Second, quality tests routinely showed higher DFT readings at the top of the tubes where the material was poured. By pouring adhesive into the top of a rotating tube and relying on gravity to do the rest, the material kept running over itself before making its way further downward.

Third, climbing atop the mezzanine and pouring the volatile adhesive by hand posed worker safety risks.

Fourth, it took a long time for the adhesive to dry in ambient air. From first application of the base coat to final drying of the topcoat, the process routinely took 12 hours.

Finally, the company had no way to test whether they’d achieved their target DFT other than by conducting destructive tests on completed tubes.

Our task was to develop an automated system that solved all five of those problems.

A 5-Stage Automated ID Tube Spray System

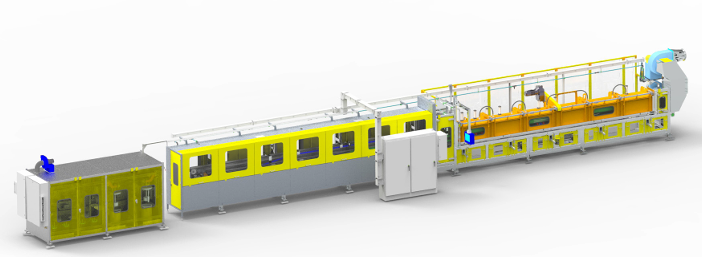

Our engineers designed a 5-stage automated ID Tube Spray System that turned adhesive application on the down-hole tubes from partly vertical to totally horizontal. Here’s how the five-stage process works:

STAGE 1: The tube is heated in a preheat oven so that its surface temperature is consistent. Consistent surface temperatures before application promote better adhesion.

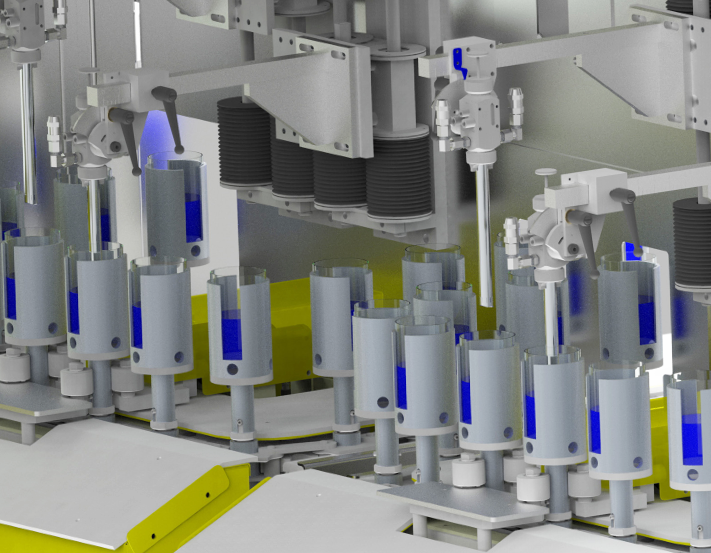

STAGE 2: The tube is transferred to a spray booth. During application, a lance exits an adjacent lance booth and enters one end of the tube in the spray booth. Then, as the lance exits the tube, its nozzle sprays atomized adhesive onto the inside surface of the tube. The tube rotates to achieve total coverage.

STAGE 3: The tube moves into a base coat drying oven for a drying cycle.

STAGE 4: The tube enters another spray booth, and a topcoat of adhesive is applied in the same way as the second stage.

STAGE 5: The topcoat dries in a drying oven just as in the third stage.

The system also included enclosed materials and adhesive mixing cabinets.

Integrating this automated system made an immediate impact.

By atomizing the adhesive rather than just pouring it, the insides of the tubes are adequately coated using far less material. The system also features flow meters showing exactly how much adhesive is dispensed. Operators can verify that they’re achieving the required DFT in real time—no destructive tests necessary.

Hands-free application of adhesive and transfer of tubes from stage to stage means workers no longer need to climb on platforms or handle dangerous chemicals.

Finally, the entire cycle now takes around two hours. Compared to the previous 12-hour cycle time, automation allowed our customer to do six times the work in the same amount of time.

Case Study #2: Chain-On-Edge Adhesive Spray System Dramatically Improves Automotive Manufacturer’s Cycle Times

When manufacturers commit to automating some of their operations, they must accept some tradeoffs that come with the territory.

Perfection is impossible. Manufacturers can’t have the fastest, cheapest, safest, and most efficient system all at once.

Below, we discuss a system we developed that has helped many automotive manufacturers alleviate some of the common challenges that accompany tradeoffs in automated manufacturing.

The Cost of Speed: Reduced Transfer Inefficiencies

Rubber-to-metal bonded parts are practically universal across automotive manufacturing applications. To keep overall production costs as low as possible, manufacturers have introduced systems that automate some or all of the assembly of these high-volume components.

A popular iteration of this idea is to send components past stationary spray nozzles that dispense adhesive. Here’s the typical setup we see:

- Cylindrical metal components are loaded onto a chain-on-edge conveyor.

- Sometimes the components pass through a preheating oven to reach a consistent temperature to optimize adhesive application.

- The parts then pass by fixed-position nozzles that spray the adhesive.

- To fully cover the diameter of the parts, they are rotated as they pass the nozzle.

This design is effective if the goal is achieving fast part-to-part cycle times, but a bigger-picture assessment reveals some shortcomings that compound on one another.

Continuous motion chain-on-edge machines, such as what’s described above, can spur increased production rates. But the increased rates these machines provide come with these critical disadvantages: Decreased transfer efficiency and reduced control over spray patterns and the amount of material applied.

Solution: Electronic Traversing Spray Guns

Productivity in manufacturing is a function of volume over time. Successful automation doesn’t always mean processes are faster. In studying systems like these, we’ve concluded that some processes can move more slowly and still be much more productive if volume dramatically improves.

The automated indexing chain-on-edge and electronic traversing spray gun system we designed proves the point. Here’s how it works:

- Parts are attached to spindles on a chain-on-edge conveyor. But instead of just one part per spindle, our system stacks multiple parts onto each spindle.

- As before, the parts enter a preheated oven.

- Next, the parts reach the spray station and stop.

- The spray station features spray guns with extension kits. When the conveyor stops, the guns extend downward into the part stack. On their way back up, the nozzles dispense adhesive.

- As before, the parts rotate on their spindles to allow for full inside diameter coverage.

- After the wands exit the stacks, the parts move on to drying.

The impact this improvement can make is compelling. Suppose that a system that processed one part at a time could apply adhesive to each part every two seconds. That’s five parts per ten seconds or 30 parts per minute.

Now, suppose the improved system stacks parts three high and the two-wand spray system applies adhesive to six parts every ten seconds. That’s 36 parts per minute. Extrapolate that over an eight-hour work shift, and the improved design can process 2,880 more parts than its predecessor.

Consider these additional perks:

- Our design allows for control of the spray application speed as well as spray timing with servo control. The guns only spray when inside the part stack. They apply the coat evenly, reducing material usage.

- Precise flow meters guarantee that adhesive is dispensed evenly every cycle. This also allows operators to detect and address adhesive flow problems faster.

- Loading and unloading of the system is much easier because it’s synchronized with stop cycles.

Overall, the system is more productive, more precise, and less wasteful. And if manufacturers choose to add optional robotic pick-and-place capabilities, human involvement is further reduced, adding to the overall precision and reliability of production.

Case Study #3: Automation Improves Quality and Consistency in Anti-Vibration Component Production

As the cases above demonstrate, advances in automation technology allow manufacturers to integrate processes that are similar to (but which improve upon) their predecessors.

But in other cases, these advances lead manufacturers to change almost everything about a process.

Such was the case when a major North American automotive supplier improved precision and consistency in manufacturing by integrating a process that looked nothing like what came before it.

A Product/Process Mismatch Hampers Efficiency

At issue was the application of adhesive to window metals used to make anti-vibration components in cars and trucks. In this stage of the process, adhesive is applied to small tubes with many “windows” cut out of them.

Our customer’s original application process was the dip-and-spin method— loading the parts into baskets, dipping the baskets into an open tank of adhesive, and then spinning the baskets to dry the parts. This process achieved total coverage of adhesive, but also caused a problem: Parts with complex geometries are at risk of adhesive pooling. This occurs when more adhesive than desired clings to part edges compared to flat surfaces.

Another problem was the open tank of solvent-based adhesive. Evaporation of solvents reduced the amount of adhesive available for application and compromised the viscosity of what was available.

The customer devised an alternative approach, which was to attach these parts to spindles on a traditional chain-on-edge conveyor system. The adhesive was applied via a spray gun that activated as parts passed by.

The system worked, but not very well. Window metal components are mostly empty space. Much of the sprayed adhesive never attached to the surface. It took much longer to ensure total coverage of adhesive compared to parts without cut-outs. The customer had merely traded old problems for new ones.

Tumble Spray System Achieves Total Coverage in Less Time

Our team determined that a totally new direction was needed to make the process faster and less wasteful.

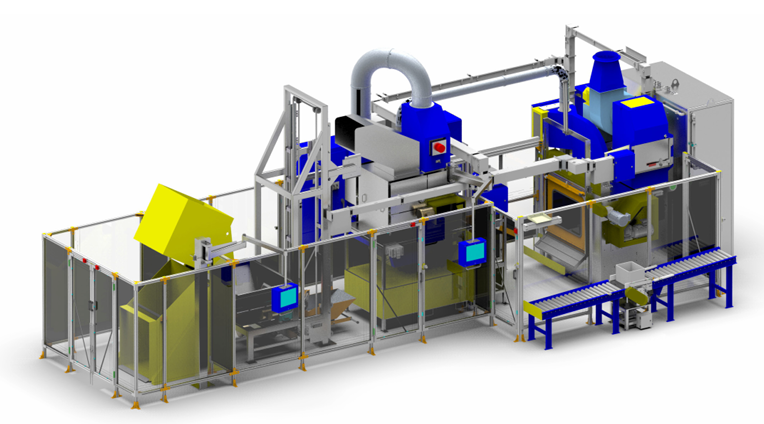

The idea: An automated tumble spray machine that featured hands-free transfer through multiple coatings. The machine also included a more systematic loading scheme whereby loads were set by weight. Here’s how it works:

- Parts are dumped onto a conveyor until the desired load weight is reached.

- Parts are then transferred to a preheated oven and heated to reach a uniform temperature.

- The parts then move to the tumble chamber where adhesive is applied for a specified amount of time to achieve full coverage.

- If parts receive two coats, they continue tumbling in the chamber as the first application dries. Then, the second coating is applied.

- Next, a topcoat is applied.

- Following all coating applications, the parts are unloaded from the chamber into containers and moved to the next processing stage.

Many facets of this system dramatically improve the consistency, quality, and efficiency of adhesive application.

First and foremost, significantly less adhesive is used because it is applied in a closed chamber in a fixed amount. It only took a couple of practice runs to determine the exact amount of adhesive required to achieve total coverage of the parts.

Next, the time it takes to apply adhesive to loads is also reduced. Rather than coat parts one at a time, many parts are processed in bulk.

Third, the hands-free transfer of parts from stage to stage improves precision and consistency by eliminating human involvement.

Finally, the machine includes bulk storage and mixing cabinets so that adhesive can be prepared more safely and stays in an ideal condition for the duration of its use.

Is Automation the Solution to Your Manufacturing Challenges?

As competition increases and global supply chains mature, manufacturers must seize the opportunity to preserve their competitive advantage.

Survey your manufacturing operations and note potential risk factors in production. Could integrating automated systems make a positive difference?

Need a hand in making the call?

Since 1994, Arnold Machine, Inc. has helped automotive, appliance, and other manufacturers save time and money, boost productivity, and improve worker safety.

Want to talk about your facility with an automation expert? Contact us now.