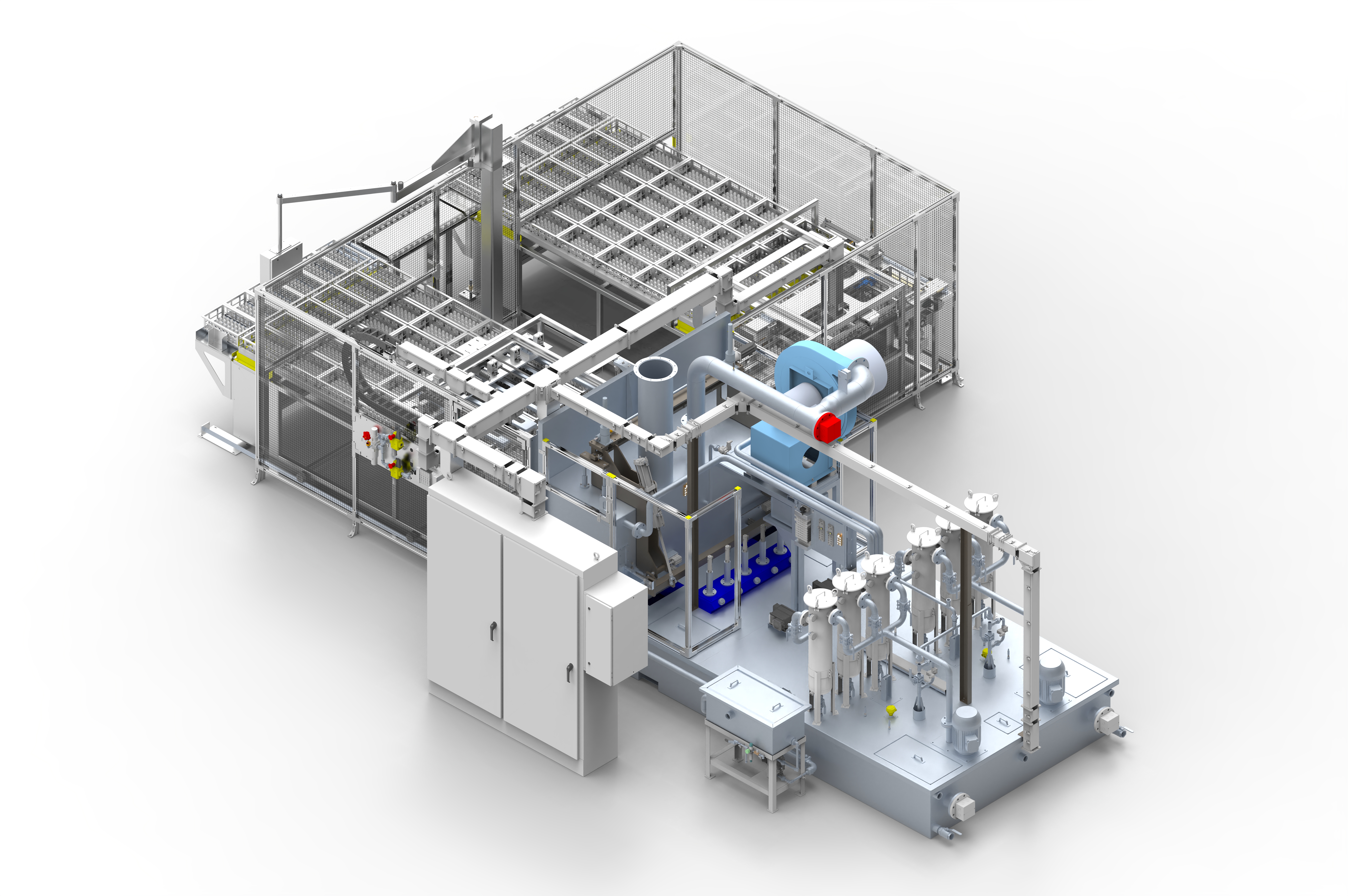

Automated Rotary Basket Immersion Washer

The Arnold Machine Automated Rotary Basket Immersion Washer is a versatile cleaning system designed for small parts with demanding cleanliness standards. This 3-stage machine includes washing, rinsing, and drying processes, and is ideal for cleaning fuel system components, electronics, stamped parts, machined components, and other intricate parts that fit within its 6" x 12" x 18" basket capacity.

Backed by over 40 years of proven design evolution, the system uses timed immersion and dynamic basket rotation to agitate and clean parts thoroughly. High-pressure spray heads enhance both wash and rinse stages, while a heated, high-pressure blower ensures completely dry parts. Freshwater rinsing can be included to meet tight quality specs. The system is operator-friendly and designed for low-maintenance, high-efficiency workflows.

Standard Features and Benefits

- Completely manufactured in the United States

- Dynamic motion basket cycle ensures complete cleaning of hard-to-reach areas

- Customizable cleaning recipes allowing simple changeover between different parts and cleaning requirements

- Lift-off access covers for easy access to chip and debris baskets

- Pump screens for protection from chips and debris

- Large tank doors for easy access for cleaning and maintenance

- Stainless steel liquid level float switches to control tank levels

- Stainless steel bag filters for wash and rinse tanks

- Solenoid valve for automatic level control of wash and rinse tank water levels

- Twelve standard Kadon 6” x 12” x 18” baskets with lids

- Integrated fork pockets and lifting eyes

- One-year warranty on parts and labor for components and workmanship, and a ten-year limited warranty on structural integrity

Specs

- Machine dimensions - 33’ long x 23’ wide x 10’ tall - approx. 15,000 lbs dry weight

- 38” operator load height with stainless steel load table

- Base machine is 10ga stainless steel

- Tank floors are pitched to a 2“ drain valve

- 500ga wash and rinse tanks, each with 15 HP, 180 gpm pumps and 60 kW electric heaters in each tank

- 15 HP centrifugal dry off blower

- 1/4 HP basket rotate drive motor

Utility Requirements

- 480 VAC / 3 phase / 60 Hz / 400 AMP power

- 3/8”, 80 PSI compressed air

- 1”, 35 PSI fresh water supply

- Two 2” NPT tank drain

Control System

- NEMA 12 main control panel, 480v, 400 amp main disconnect

- UL-approved 24 VDC controls package with Allen-Bradley CompacLogix PLC and Weintek 10” touch screen HMI

- Pre-programmed wash cycle recipes customizable to specific needs

Optional Items

- Ultrasonics

- Filter housing pressure transmitters

- Remote troubleshooting

- Mist Collector

- 25ga Coalescing Oil Removal System (can be added to wash and/or rinse circuits)

- Fresh water rinse cycle

- Blow-off heat (25 kW)

- Tank insulated with stainless steel skin

- Recommended for water temperatures above 140 F and overall heating efficiency

- Automatic Chemical Monitoring & Addition

- Viewing window with integrated lighting

- Single Point Tank Drain

- Canadian CSA Certification

- Service Plan Options

- Additional Baskets & Customized Fixturing

COMMON APPLICATIONS

The Rotary Basket Immersion Washer is widely used in industries where part precision and cleanliness are non-negotiable. Typical applications include cleaning fuel rails, hydraulic fittings, aluminum castings, fasteners, electronics housings, and transmission components. It’s especially effective for parts with blind holes, intricate geometries, or heavy contamination.

HOW AUTOMATED ROTARY BASKET IMMERSION WASHERS WORK

This immersion washer uses a dynamic, multi-stage process to clean parts thoroughly while minimizing manual labor:

- Basket Loading: Operators load parts into 6" x 12" x 18" stainless steel baskets. Multiple baskets can be queued for continuous processing.

- Stage 1 – Wash: Parts are immersed in a heated wash tank and agitated with basket rotation. High-pressure spray heads assist in maximum soil removal.

- Stage 2 – Rinse: A heated rinse follows, enhanced by directional spray heads. This helps remove detergent residue and meet final cleanliness specs.

- Stage 3 – Dry: A centrifugal blower completes the cycle, drying all surfaces before parts exit the machine.

- Unload & Repeat: Clean parts are removed, and the next basket enters—fully automated based on cycle programming.

Trust Arnold Machine with Your Parts Washing Needs

Are you looking to improve your current parts-washing process? Arnold Machine specializes in designing and manufacturing custom parts washers tailored to your needs and requirements. We ensure that your equipment meets the highest cleanliness standards, providing both efficiency and durability. Contact us today to get a quote and discover how we can optimize your parts-washing process.

Automated Rotary Basket Immersion Washer FAQ

-

Can the Automated Rotary Basket washer accommodate very tight cleanliness specs?

-

How much operator involvement is needed to run the Automated Rotary Basket washer?

-

What types of parts are best suited for this system?

-

How does your Automated Rotary Basket washer compare to your competition when it comes to price?

OTHER PARTS WASHING SYSTEMS AND RELATED MACHINES

Rotary Basket Washers

Our rotary basket systems offer batch cleaning with rotary spray action and optional multi-stage configurations. These washers provide precision and repeatability for parts that don’t require immersion-based cleaning.

Custom Parts Washer

When standard systems don’t fit the application, our custom washers are engineered to meet unique part geometries, cleanliness specs, and automation needs. Perfect for specialized or high-spec cleaning challenges.

Rotary Table Washer

Offers efficient, precision cleaning for large parts or small batches using a rotating turntable and targeted spray. Commonly used in maintenance, rebuild, and medium-duty industrial cleaning applications.

Pass-Through Washer

Inline, high‑volume parts cleaning for continuous or indexed material flow. Designed to support multi‑stage processes with minimal manual handling.

Featured Posts

8RB50 Parts Washer

Implementation of 3-Stage 8RB (8-Basket Rotary Basket) Washer for Increased Capacity