Implementation of 3-Stage Rotary Basket Washer for Increased Capacity

Murotech Ohio, a major supplier of metal stampings to companies like Honda, Toyota, Nissan, and GM across the United States, Canada, and Mexico reached out to Arnold Machine to add another washer to production. The client had previously purchased a Rotary Basket washer and sought to add an identical machine to increase capacity based on their positive experience.

Challenges:

The project faced minimal challenges, as it involved a repeat customer seeking an additional machine identical to their existing one.

The Solution/Function:

Heated Wash:

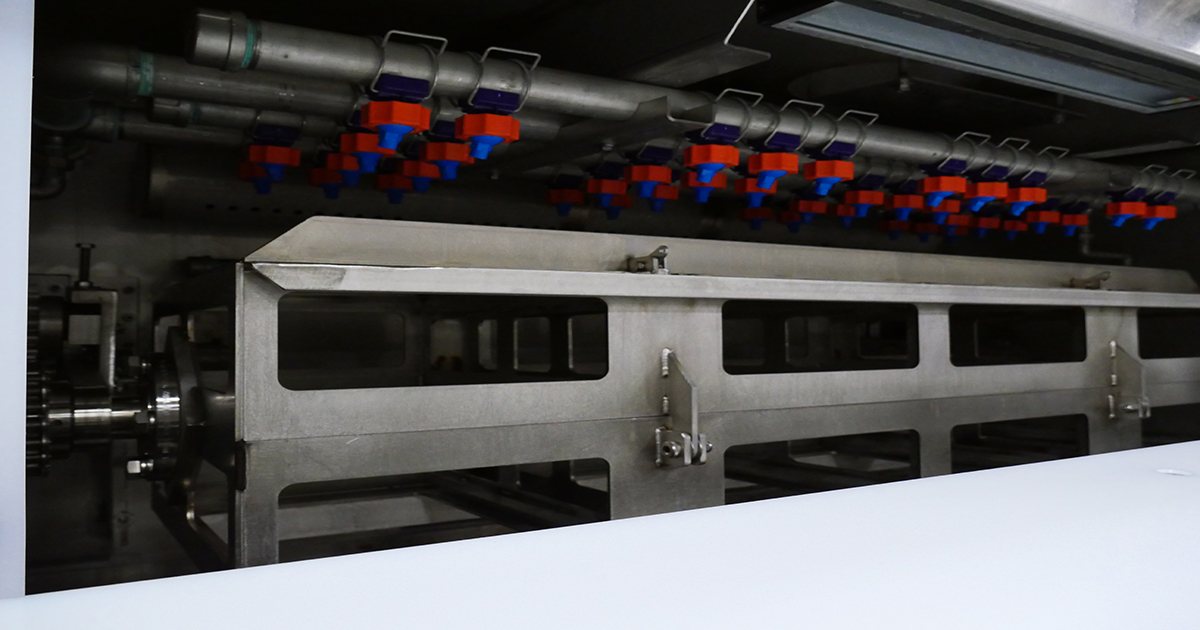

The operator manually loads and secures four (4) Kadon baskets into the stainless-steel rotating fixture. The operator then rotates the fixture and loads another (4) Kadon baskets. After that, the operator initiates the heated wash cycle by depressing dual palm buttons and the cabinet door closes. During the heated wash cycle, high-volume stainless-steel headers and polypropylene nozzle assemblies will spray the exterior of the basketized parts as they rotate. A second stainless steel header will be used to fill the lower basin for the immersion process. Once full, the fixture will be lowered into the basin, completely immersing the parts as they rotate for enhanced cleaning. After the immersion cycle, the wash basin will be drained. The wash solution will be continually filtered and recirculated through a stainless-steel bag filter housing. Upon completion of the heated wash cycle, the fixture and tank basin will be allowed to drain for a predetermined amount of time prior to starting the heated rinse cycle.

Heated Rinse:

- The heated rinse cycle mirrors the design and function of the heated wash cycle.

Heated Blow-Off:

- A blower, heater, and air knife strip excess moisture for quick drying.

- The door opens for manual unloading after drying.

How End Product Helped Company:

The integration of the second Rotary Basket washer allows our client to meet cleaning needs with increased capacity. By adding the second washer, the client can pursue additional business confidently, knowing they can accommodate growing demands. The client was very happy with both the second Rotary Basket washer and the service received during installation.

Arnold Machine and the customer are looking forward to future collaborations – potentially including the addition of a third washer when they are ready for further expansion.

"The Arnold Machine team did great. You kept us up to date as with the progress of the build and all the way to set up...I am very pleased with your customer service and Tech guys. When ever we need help on anything, the Arnold Team was there to help out."

-Jeff Thobe

Murotech Ohio

Rotary Basket Washers Can Help You Increase Your Production Capacity

Our Rotary Basket Washers helped Murotech Ohio increase their production capacity and they can do the same for you. We custom build our parts washers with your unique application requirements and desired capacity in mind. Use the link below to learn more about our Rotary Basket Washers and see if they are the right fit for your operation.