Manufacturer’s Guide to Launching Automated Operations

Industrial processes have changed.

The pursuit of increased quality, reduced risk, and cost control by OEMs and their Tier 1 suppliers has created today’s highly technical—and sometimes highly automated—manufacturing operations.

Firms that intend to continue doing business in the automotive and other highly regulated sectors need to evolve to stay competitive. In this guide, we dig into two key phases of an owner’s decision to integrate automation into their production.

- The initial comparison between human labor and automated systems.

- An assessment of whether your specific operations are best served by fixed or flexible automated systems.

Automation vs. Human Labor: Here’s What to Consider

Automation has changed the dynamic between man and machine. But woeful stories of people losing their jobs to robots overlook a key fact about today’s economy: Automated manufacturing systems have played an outsized role in the recovery from the 2008 recession and the continued strength of the American economy.

The writing is on the wall: Automation is here to stay. In the case of some businesses, their survival depends on it. Meanwhile, the world’s leading thinkers say businesses are better served by finding ways to transition their human workforce into roles where they can excel.

If you’re considering automation, read on for some guidance on how to integrate it where it’s most appropriate.

Determining Cost: Automation vs. Cost of Labor

Cost is the most common starting point in these decisions. Begin by clearly defining your goals and identifying the indicators used to gauge success (these might be revenue targets, scrap rates, rework requests, or downtime/uptime ratios). These metrics are the key impartial benchmark you can refer to as you decide whether an automated or human setup is best for your business.

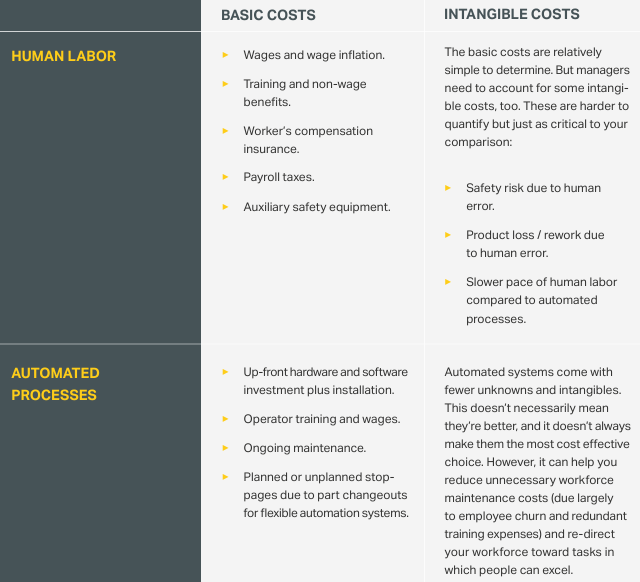

Next, collect as much information as you can about all the costs associated with human labor and automated systems.

Automated systems can help redirect your workforce toward tasks in which people can excel.

Calculating ROI: Automated vs Manual System

The key question is whether the up-front cost to implement automation will pay off within the lifecycle of the system. ROI can come from more than one place:

- The replacement of enough labor to result in cost savings that make the automated system worth the expense.

- The increased quality and capacity, and ensuing increased revenue potential, that an automated system can bring outweigh the lower-cost but lower-volume manual labor setup.

Often, the combination of reducing labor and increasing high-quality output will result in a positive ROI in the long term.

Hypothetical ROI Calculation

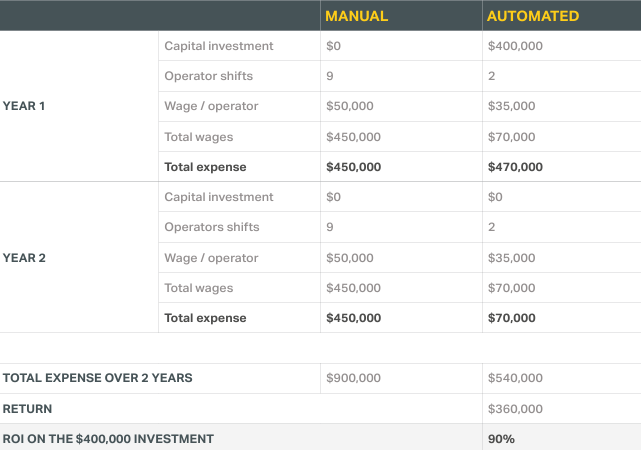

The following calculation is an example meant to serve as a template for your application. Costs of custom automation equipment can vary widely depending on your needs. Note that this calculation does not factor in quality, throughput, interest, depreciation, maintenance, training, etc.

Suppose you have a partially manual system requiring three skilled operators working three shifts per day. Assume that the cost per operator is $50,000 a year for a total annual labor expense of $450,000.

Alternatively, suppose you identify a fully automated system that costs $400,000 to design, build, and install. It will need one unskilled operator at $35,000 a year for two shifts per day, totaling $70,000 a year. Training is relatively inexpensive because the operator simply loads and unloads the machine. The total expense for automation is $470,000, translating to a first-year ROI of -$20,000 ($470,000 automated system minus the $450,000 partially manual system).

However, the payoff begins in the second year because there is no capital investment for the automated system. With reduced labor costs, yearly production expenses are significantly lower compared to the manual system. Over two years, production with the automated system costs $540,000, while the manual system would’ve cost $900,000. That represents a return of $360,000, or a 90% ROI.

Is Automation Right for Your Process?

Automated systems are generally recommended for high-volume orders. It’s an even more attractive option when consistent quality and repeatability in a production run are paramount. Automated systems that increase consistency and reduce scrap rates can be further engineered to inspect parts before they proceed through the rest of the manufacturing process. If there’s an issue, the part is automatically scrapped before more components are added or further processing takes place, saving time and material input. This will come at a significant cost up-front, but the machine’s high capacity and minuscule error rate mean it will begin to pay itself off.

Human operators cannot perform at maximum speed for their whole shift and expect to produce perfect parts every time. We wouldn’t want them to try. The effects could be disastrous.

On the other hand, human labor generally comes with lower upfront costs and is valuable for low-quantity runs, unique one-off projects, or research and development trials. In addition, operators can offer real value for processes that require critical thinking or where automation is not economical to integrate.

The automotive industry has embraced automation and will continue integrating it due to the better quality, efficiency, and return on investment it provides. Accordingly, industry suppliers who choose to integrate automation have a leg up on the competition.

Such was the case when Arnold Machine built an automated assembly system for an engine mount for a major automobile manufacturer who wanted to decrease labor while increasing the production rate and quality. The machine we built utilized a FANUC robot, hydraulics, and custom tooling that removed operators from difficult-to-verify processes and ultimately reduced the cycle time from more than a minute to less than 45 seconds.

For our customer, it was well worth the investment.

What’s Next?

After deciding to incorporate automated systems in your manufacturing operations, it’s important to assess your operations to determine what form those systems should take.

Should you opt for predominantly hard systems engineered for a small range of specific tasks, or are you better served with flexible systems designed to complete a wider range of operations with minimal downtime? We devote the remainder of this guide to that discussion.

Comparing Flexible vs. Hard Automation

OEMs and Tier 1 suppliers serving the automotive industry have increasingly turned to automated manufacturing as they push to ensure the quality of the parts they make is maintained.

But even the field of automated manufacturing is evolving. Part producers hoping to stay competitive rely on having the right mix of fixed and flexible automation systems integrated within their work.

Choosing flexible vs. hard automation systems is about understanding the types and volumes of parts your customer requires and then matching those requirements to the appropriate manufacturing process.

Use Cases for Flexible Automation

Flexible automation systems feature base machines designed to accept interchangeable tooling. This allows for the seamless, speedy manufacture of parts similar enough that only minor tooling changes need to be made without affecting the machine in any other way.

For example, automotive suppliers often make similar parts across a make’s lineup. In instances where the minor differences among those parts can be overcome with a tooling change and nothing more, a flexible automation system makes sense.

Another example is the frequent (though usually minor) changes to some automotive parts from model year to model year. If manufacturers and their customers recognize that these minor changes can be accomplished with updated tooling on a flexible automation setup, costs and project timelines can be reduced.

Finally, flexible automation is a good fit for operations with high product variation, with abbreviated timelines when downtime due to equipment change-outs is a luxury they can’t afford. If you’re searching for more cost savings, look for opportunities to collaborate with the OEM or Tier 1 partners to see if they can design with flexible automation systems in mind.

Cost Considerations for Flexible Automation Systems

Regardless of whether an automated system is hard or flexible, the up-front investment is significant. It’s the base machine that’s most expensive to build.

But when flexible automation systems are matched with appropriate manufacturing processes, steep up-front costs are overcome. Here’s how:

- Flexible automation eliminates some of the cost redundancies associated with buying, operating, and maintaining multiple fixed systems. They also maximize throughput —and therefore revenue— relative to square footage of floor space.

- Implementing flexible automation ahead of time in anticipation of a potential design variation is always cheaper than doing it later. It reduces downtime and eliminates surprises, too.

- Flexible systems can help secure future business, signaling to customers you’re prepared today for the demands of tomorrow.

The key is appropriately matching processes with a flexible automation system. Consult your automation partner and your customers to help develop the flexible automation system tailored to your unique needs.

Example of Flexible Automation at Work

The automotive industry has embraced flexible automation because robots can be integrated with interchangeable end-of-arm tooling and stored part recipes. In addition, robots increase throughput and repeatability at a lower cost than more error-prone human operators.

Case in point: Arnold Machine developed a flexible robotic spray machine that applies an adhesive coating on multiple parts within a single-dimensional window. Its robot is programmed to perform a custom spray pattern according to each variation of part our customer planned to run through the system.

Our team designed the machine to seamlessly switch from one part to the next. An operator simply selects a part on the machine’s HMI screen to make the adjustment.

Right-Fit Processes for Hard Automation

We discussed above that flexible automation systems help manufacturers overcome challenges associated with the ways some of the parts they make are evolving. But that evolution isn’t universal. Some parts and processes don’t change that much. When that’s the case, a hard automation system might make the most sense.

For instance, some automotive parts stay the same for years before they’re redesigned. In such a scenario, hard automation is preferred. In these systems, it’s all about long-term repeatability and quality. No retooling, no constant redesign. When parts go unchanged across multiple models over long periods, it’s an opportunity to secure long-term cost stability.

Hard automation is also a good fit when parts are so unique or so complex that it only makes sense for a one-off custom machine to perform a process.

Understand Overall Equipment Effectiveness (OEE) to Enhance Production Planning

OEMs and Tier 1 suppliers use this critical metric to judge a system’s productivity. It should be specified before any of your equipment is sourced, so you can inform your automation partner which OEE goals an automation system will need to meet.

The following factors combine to demonstrate OEE:

- System availability, which measures whether your system meets its planned production timeline by accounting for planned and unplanned work stoppages.

- System quality, which measures how consistently your system performs without part defects or rework.

- Performance rating, which measures whether your process is running at optimum efficiency.

OEE calculations can vary between facilities based on their individual goals, internal requirements, and customer requirements. Arnold Machine works closely with customers to develop both hard and flexible automated systems that meet OEE goals while keeping costs in check.

Achieve Balance in Fixed vs. Flexible Automation

A host of variables dictate whether manufacturing processes should be hard- or flexibly-equipped. Project managers should think in terms of balance, knowing that in most automotive manufacturing settings, both types of automated systems are used. The art is in implementing the right mix that keeps your processes cost-effective and adaptable at the same time.

Arnold Machine uses its expertise in both fixed and flexible automation systems to guide OEMs and Tier 1 suppliers toward achieving the balance that enhances the quality and efficiency of automotive manufacturing.

If you have more questions about the benefits of automated system integration or want to discuss getting an automated system online in your plant, contact our team.