HOW TO CHOOSE THE RIGHT PASS-THROUGH PARTS WASHER FOR YOUR APPLICATION

When it comes to industrial parts cleaning, pass-through parts washers, also known as conveyor parts washers, offer a powerful and efficient solution for high-volume manufacturing environments. Designed to handle continuous cleaning of parts on a conveyor, these systems are ideal for production lines where speed, consistency, and cleanliness are top priorities.

However, not all pass-through parts washers are created equal, and selecting the right one for your operation requires careful consideration of your specific cleaning requirements, production goals, and facility constraints. Below, we’ll walk through the key factors to consider when choosing the right pass-through parts washer for your application.

1. UNDERSTAND YOUR CLEANING REQUIREMENTS

The first step in selecting the right parts washer is understanding exactly what needs to be cleaned. Consider:

- Part size and geometry: Are you cleaning small, intricate components or large, heavy parts? Complex geometries may require adjustable spray manifolds or high-pressure nozzles to ensure complete coverage.

- Contaminant type: Grease, oil, coolant, chips, and carbon deposits each require different cleaning chemistries, temperatures, and pressures.

- Cleanliness level required: Determine whether parts need to be visibly clean, dry, or meet a specific technical standard (e.g., for automotive or aerospace applications).

- Drying requirements: Determine how dry parts must be post-wash. In some cases, light moisture may be acceptable, while assembly-ready parts may require enhanced drying methods.

A clear understanding of these variables helps determine the necessary washer configuration, wash and dry stages, and chemical compatibility.

2. CHOOSE THE RIGHT WASHER CONFIGURATION

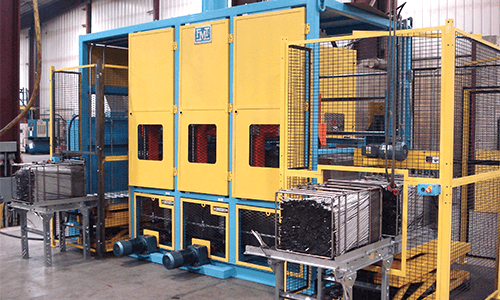

Pass-through parts washers come in a variety of configurations designed to match different part sizes, shapes, and production environments. Selecting the right configuration ensures efficient cleaning, optimal throughput, and easy integration with your existing process.

Here are six common types of pass-through parts washers to consider:

- Standard 3-Stage Continuous Belt Washers: A reliable choice for most high-volume cleaning applications, these washers include wash, rinse, and dry stages in a continuous flow. They’re ideal for handling consistent part sizes and achieving high throughput with minimal operator intervention.

- Parallel Chain Washers: Designed for large, heavy, or uniquely shaped components, parallel chain washers provide stable support and precise part transport through each cleaning stage. They’re particularly well-suited for heavy-duty industrial parts and assemblies.

- Monorail Washers: Commonly used in paint and coating operations, monorail washers move hanging parts through multiple cleaning stages, allowing for complete 360-degree coverage. They’re an excellent choice when part orientation and surface exposure are critical.

- Roller Conveyor Washers: Ideal for bulky or flat parts such as castings or panels, roller conveyor systems enable smooth, consistent transport through wash and rinse zones while accommodating heavier loads.

- Immersion Conveyor Systems: These washers submerge parts into an agitated cleaning solution for deep, thorough cleaning. They are especially effective for complex geometries or components with internal passages that are difficult to reach with spray nozzles alone.

- Incline Belt Washers: Perfect for compact layouts or when space constraints exist, incline belt washers move parts upward through cleaning and drying stages, optimizing footprint while maintaining high performance.

Each configuration offers unique advantages depending on your part design, contamination level, and production flow. Arnold Machine engineers can help determine which system type delivers the best combination of cleaning power, efficiency, and flexibility for your specific application.

3. DETERMINE THE NECESSARY WASH STAGES

A pass-through system can be as simple or as complex as your process demands. Typical stages include:

- Pre-Wash: Removes heavy soil and debris.

- Wash: Uses detergent and heated water for deep cleaning.

- Rinse: Flushes away detergent and contaminants.

- Dry: Removes moisture before the next production step.

Some applications may also require rust inhibition, blow-off drying, or precision rinsing. Arnold Machine can tailor the number and type of stages to meet your cleanliness and throughput goals.

4. CONSIDER THROUGHPUT & PRODUCTION DEMANDS

The right pass-through washer must align with your production rate. An undersized system could cause bottlenecks, while one that’s oversized may waste energy and space. When evaluating throughput, consider:

- Number of parts per hour

- Conveyor speed requirements

- Part geometry (size and shape)

- What is being washed off

Arnold Machine’s engineers can help calculate the optimal balance between cleaning performance and line speed to ensure efficient operation.

5. EVALUATE ENERGY EFFICIENCY & MAINTENANCE NEEDS

Modern pass-through parts washers are designed to minimize water, energy, and chemical usage. Look for features such as:

- High-efficiency pumps and heaters to reduce operating costs

- Filtration and oil skimming systems to extend bath life

- Insulated tanks and enclosures to maintain consistent temperatures

- Easy-access panels for simplified maintenance

- Chemical monitoring and addition capabilities

Energy-efficient design doesn’t just save money—it also supports sustainability goals and reduces your overall environmental footprint.

6. THINK ABOUT INTEGRATION & AUTOMATION

A pass-through washer should integrate seamlessly with your existing production line. Whether you need automated loading and unloading, PLC controls, or data collection capabilities, a custom-designed system ensures compatibility and ease of use.

Arnold Machine’s team can fully automate your washer to work in tandem with conveyors, robotics, or other upstream/downstream processes for a fully integrated solution.

7. PARTNER WITH AN EXPERIENCED EQUIPMENT MANUFACTURER

Finally, work with an experienced equipment builder who understands both your cleaning challenges and your production environment. At Arnold Machine, we design and manufacture custom pass-through parts washers built for performance, reliability, and longevity. Every system is engineered to your exact part specifications, throughput requirements, and facility layout.

From initial concept and design through fabrication, testing, and installation, our team ensures your washer performs exactly as needed, today and for years to come.

READY TO FIND THE RIGHT PASS-THROUGH WASHER FOR YOUR APPLICATION?

Choosing the right pass-through parts washer can dramatically improve cleaning consistency, reduce labor, and increase productivity. Whether you need a compact single-stage unit or a fully automated multi-stage system, Arnold Machine can design a solution that fits your process perfectly.

Contact us today to discuss your application and learn how our custom-engineered pass-through parts washers can optimize your cleaning process.