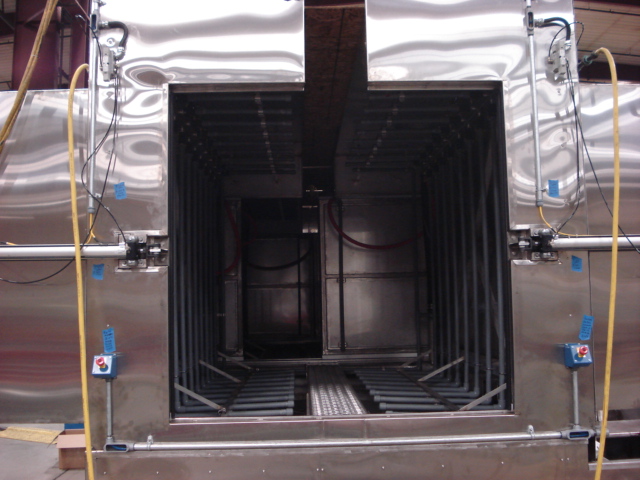

Monorail Pass-Through Washers

Automated, In-Line Cleaning for High-Volume Production

Arnold Machine’s Monorail Parts Washers are designed to deliver consistent, high-quality cleaning while seamlessly integrating into your production process. Built for continuous operation, these systems use an overhead monorail to transport parts through multiple cleaning stages with precision and repeatability. The result is improved throughput, reduced labor, and dependable cleaning results for even the most complex or heavy components.

Benefits of Monorail Washers

Key Features

- Automated Overhead Monorail Transport

Provides smooth, controlled movement of parts through each cleaning stage with minimal manual handling. - Custom Cleaning Stages

Configurable wash, rinse, and dry zones tailored to your cleanliness requirements. - Heavy-Duty Industrial Construction

Built with robust materials and corrosion-resistant components for long-term performance in demanding environments. - Advanced Control Systems

PLC-controlled operation with intuitive HMI allows for easy recipe management, monitoring, and adjustments. - Flexible Part Handling

Designed to accommodate a wide range of part sizes, geometries, and weights.

Typical Applications & Industries

Arnold Machine Monorail Parts Washers are commonly used in:

- Automotive and Tier 1 suppliers

- Heavy equipment manufacturing

- Aerospace and defense

- Machining and metalworking

- Fabrication and assembly operations

They are ideal for cleaning castings, machined components, welded assemblies, and other complex parts prior to coating, assembly, or inspection.

Designed & Built by Arnold Machine

Every Monorail Parts Washer is engineered and fabricated by Arnold Machine’s experienced team in the USA. Whether you need a standard configuration or a fully customized solution, we work closely with you to ensure your system meets performance, space, and production goals.

TRUST ARNOLD MACHINE WITH YOUR PARTS WASHING NEEDS

Looking to meet precise cleanliness standards while minimizing labor and downtime? Arnold Machine's Rotary Basket Immersion Systems are engineered for performance, flexibility, and reliability. Every unit is built in the U.S. using 304 stainless steel and supported by a dedicated service team.