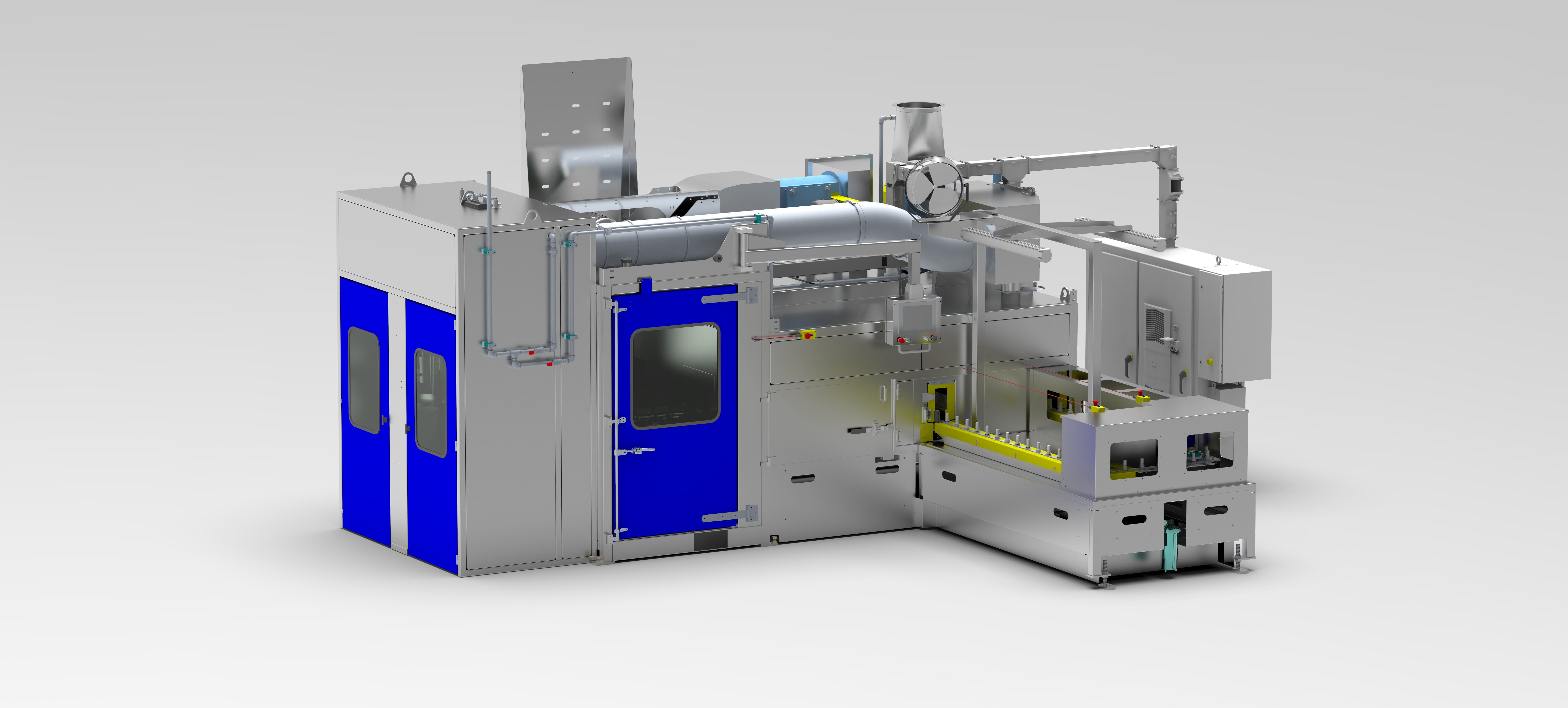

Roll Transfer Coating System

The Arnold Machine Roll Transfer Coating System is commonly used for high-volume, smooth-diameter tubular parts that require external coating coverage. The system can apply paint, adhesive, rust preventative, lubricant, or virtually any other solvent or water-based material needing to be applied. The system utilizes an automatic feeding and load/unload that does not require an operator to manually operate.

The machine is Class 1, Division 1 explosion-proof with fully enclosed coating and heating stages designed for 100% transfer efficiency of coating materials. The system can apply up to three different materials with a drying stage between each. The system also includes a preheated stage prior to the first coating station. Finished coated and dried parts are automatically unloaded into a bulk container.

Benefits of Roll Coater Systems

Standard Features and Benefits

- Completely manufactured in the United States

- Automatic load and unload

- Up to 2,880 parts per hour coated and dried

- Fluid control system includes:

- 5 ga, stainless steel fluid pot for each material with level sensors

- Integrated fluid recirculation system

- Integrated fluid agitation

- Integrated fluid filtration

- Integrated coating detection sensing and automatic failed part diversion

- Integrated electric pre-heat and drying stages

- Arnold Machine 100% air capture coating booth design to prevent solvent laden air from escaping the machine. NFPA Class 1, Division 1 explosion-proof

- Fresh air intake

- Safety interlocked access doors with viewing windows

- Water based fire suppression system

- Ability to create and save the multi-point, custom configuration recipe in the touch screen

- Operator cycle start/stop & emergency stop

- Integrated lifting eyes and forklift pockets

- Carbon steel construction, powder-coated 7035 Machine Grey

How Roll Coater Systems Work

Here’s how our roll coater system efficiently coats your parts for consistent, automated results:

- Parts Loading: A bulk tote is placed onto a powered dumper. Once the operator clears the safety light curtain, parts are dumped into a hopper and conveyed via a flighted or stepper feeder to a belt conveyor.

- Shaft Loading: Dual-actuated mechanisms place parts onto spindle shafts mounted to an indexing chain conveyor, moving two parts at a time.

- Temperature Increase: Parts travel through an electric oven loop to raise their temperature before coating.

- Primer Application: A rotating applicator wheel applies Chemlok primer to the part’s outer surface.

- Top Coat Application: After another oven loop, parts receive a top coat via a second applicator wheel.

- Final Coating & Part Monitoring: A third loop allows for a final material coating. Dual sensors confirm part rotation; if rotation is not detected, the part is flagged for diversion.

- Cooling & Unload: Parts cool to 125-130°F before exiting the spindle and sliding down a gravity chute. Defective parts are removed via a pneumatic diverter.

- Part Counting & Collection: Finished parts are counted by a laser sensor and collected into a tote. When full, the operator swaps the tote manually.

Specs

- Machine Dimensions

- 12 ft. tall x 20 ft. wide x 22 ft. deep

- Utility Requirements

- 480 VAC - 3 phase - 60 Hz - 100 AMP

- 3/4 in., 60 PSI compressed air

- 1 in., 35 PSI fresh water supply

- 14 in. Exhaust Duct outside of the building

- Control System

- NEMA 12 main control panel 480v main disconnect

- UL-approved 24 VDC controls package with Allen-Bradley CompacLogix PLC and ProFace 10 in. touch screen control panel

- Red, yellow, green stack light

- Adjustable temperature, conveyor speed, and roll speed

Optional Items

- Spare roller assembly and pans

- Material flow rate sensor

- Canadian CSA certification

- Service plans and options

Common Applications

Roll transfer coating systems are ideal for cylindrical parts requiring uniform external coverage. These include:

- Suspension bushings

- Tubular metal fasteners

- Bushings, pins, or sleeves used in chassis, drivetrain, or stamped assemblies

- Parts requiring rubber-to-metal adhesive coatings

Their ability to handle small, lightweight parts (under 2 lbs) at high throughput makes them especially effective for Tier 1 automotive suppliers and OEM production lines.

Trust Arnold Machine with Your Coating System Needs

At Arnold Machine, we understand the critical role of reliable and efficient coating systems in your manufacturing process. With extensive experience designing automation equipment across various industries, we’ve developed a deep understanding of diverse coating needs.

Our team of seasoned engineers leverages this expertise to create high-performing, repeatable, and safe solutions tailored to your specific requirements. We remain at the forefront of automation technology through continuous learning and collaboration. Strategic partnerships provide early access to emerging technologies, which we actively integrate into customer solutions.

Roll Coater System FAQ

-

How does the system apply adhesive material and what is the transfer efficiency on a roll coater?

-

How many operators are required to operate the system?

-

Does the system utilize any devices to detect primer and top coat?

Other Coating Systems and Related Machines

Chain-on-Edge Conveyors

Boost your profitability with our innovative CoE systems. Advanced robotics automate your processes to increase transfer efficiency and reduce labor costs.

Tumble Spray Coating Systems

Achieve unmatched protection and efficiency with our fully automated Tumble Spray systems. Experience 100% coverage, significant labor savings, and consistent results in your coating operations.

Interior Diameter (ID) Tube Spray Machines

Precision coat interior tube surfaces with our specialized ID spray machines. Optimize your process with our solutions designed for consistent results and efficiency.

Automatic Viscosity Bulk Mixing Stations

Maintain consistent material viscosity and streamline your production. Ensure coating results and minimize downtime with our reliable, automated solution.