Two Coat Chain-On-Edge (CoE) Coating System

The Two Coat Chain-On-Edge Coating System is designed for fast, precise, and consistent multi-layer coating, ideal for demanding, high-volume production.

It features a rotate-and-spray mechanism within a fully enclosed explosion-proof booth for safety and compliance. A servo-driven chain conveyor provides continuous or indexed part movement, and advanced control systems enable repeatable results.

Looking for a high-throughput coating solution tailored to your operation?

Benefits of Two Coat Chain-on-Edge Coating Systems

How Two Coat CoE Coating Systems Work

Arnold Machine Chain-on-Edge cleaning lines streamline the coating process by transporting parts through a series of zones designed for loading, pre-heating, spray application, drying, and cooling. We designed the system to utilize and apply one of 2 coating materials at any time throughout the process – solvent or water-based adhesive primer and top coat.

Here’s a detailed look at how they work:

- Load Zone: It is the operator’s responsibility to manually load the appropriate fixtures and parts onto the spindles presented in the load area. This area will have 6' of accessible fixtures for loading and also contains an overhead light for easy visualization. The load zone includes an operator work fan.

- Pre-Heat Zone: In order for the primer to adhere to the part it needs to be pre-heated to a predetermined temperature. The pre-heat zone in the oven consists of forty-eight (48) spindles to maximize cycle time and oven efficiency. Once the parts have reached temperature in the pre-heat zone, they will convey to the primer spray zone.

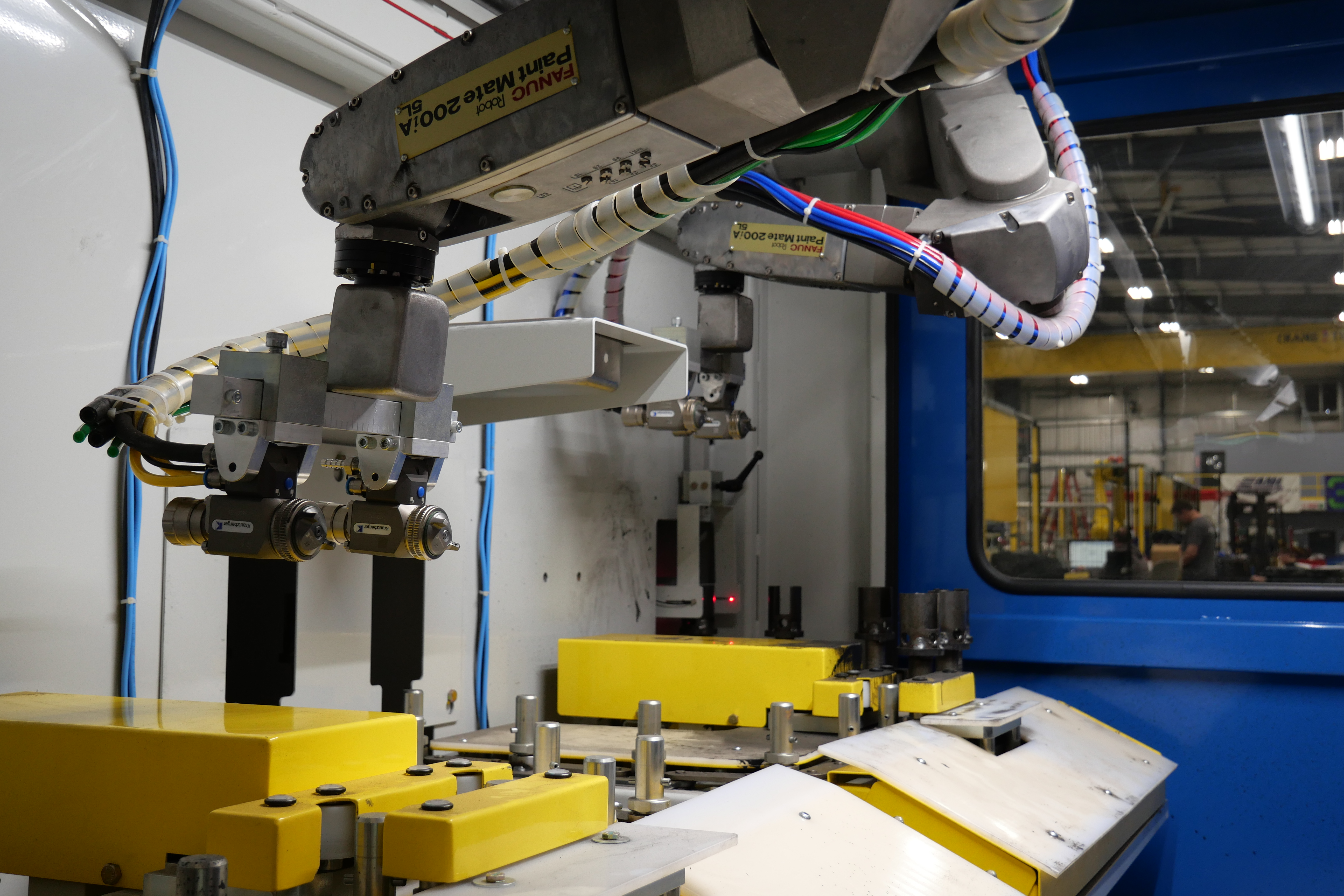

- First Spray Zone: Parts will enter the spray booth and the spindle will be engaged with a variable speed belt drive system for part rotation. Two (2) Krautzberger spray guns mounted to FANUC Paint Mate robots are utilized to apply the primer to the part. The Spray zone is designed to control air flow for maximum transfer efficiency and to accommodate ease of clean up and maintenance. Between the first spray zone and the first dry oven, a Keyence flow sensor will be utilized to verify a specific amount of primer has been sprayed from the spray gun, if primer flow is not detected, top coat will not be applied to the part in the top coat zone. The primer pressure pot will be located in the material storage cabinet and will be provided with all gun connections to the pot.

- First Coat Dry Zone: After parts exit the first spray zone, they will enter back into the oven for a series of cycles in the first dry zone. This area will allow for additional dry time of the first before the top coat is applied. There will be eight (8) spindles in this zone.

- Second Spray Zone: Parts enter the second coat spray zone from the first dry zone and the spindle will be engaged with a variable speed belt drive system for part rotation. Two (2) Krautzberger spray guns will be utilized to apply the second coat to the part. The guns will be fixed mounted to a FANUC Paint Mate robot. This spray zone will be designed to control air flow for maximum transfer efficiency and to accommodate ease of clean up and maintenance. The second coat pressure pot will be located in the material storage cabinet and will be provided with all gun connections for the pot. Along with first spray zone, the second coat zone will also utilize Keyence flow sensors. If second coat flow is not detected, the machine will send an alarm to the operator for part inspection and removal.

- Second Coat Dry Zone: After parts exit the second coat spray zone, they then enter the second coat dry zone. This zone consists of fifty-two (52) spindles that allow the final coat to fully dry before being handled by an operator. Once the part is fully dry it will enter the cooling zone in order for the part to decrease temperature for operator manual unload.

- Cooling Zone: Parts exiting the top coat dry oven will enter the cooling zone. Parts will exit the cooling zone and be presented to the operator for unloading. The operator is responsible for performing a visual inspection of the coating quality and placement into the appropriate customer supplied container before loading the next part and continuing the cycle over. An operator light will be provided in this zone for ease of visualization and product review.

Common Applications

Chain-on-edge conveyors are commonly used to coat straight or profiled cylindrical substrates that require inside or outside diameter coverage.

They efficiently coat multiple faces of a part when needed. Typically, they are used with aluminum or steel substrates ranging in diameter from 1 inch to 5 inches and up to 8 inches tall.

Our CoE conveyors are ideal for large production runs with consistent part sizes and shapes. These systems automate the painting process and reduce the need for manual involvement.

This leads to excellent process control and ensures each part is painted similarly. However, it is important to consider part size limitations and variations when choosing this system.

Specs & Features

- Machine dimensions – 12ft tall x 17ft wide x 24ft long

- Utility requirements;

- 480 VAC – 3 phase - 60 Hz – 150 AMP power

- 1”, 75 SCFM, 60 PSI compressed air

- 1”, 35 PSI fresh water supply

- 14” Exhaust Duct outside of the building

- Control system;

- NEMA 12 main control panel with sequester 480v main disconnect.

- UL approved 24 VDC controls package with Allen-Bradley CompacLogix PLC and ProFace 10” touch screen control panel.

- Red, yellow, green stack light

- Servo conveyor drive with options for constant motion or index and dwell

- Adjustable rotate speed

-

Utilities

-

Oven

-

Spray Booth

-

Fluid Delivery

-

Safety Features

Optional Items

- Recipe driven, programmable vertical gun position.

- Recipe driven robotic gun position or spray pattern.

- This option includes an automatic gun cleaning feature.

- Recipe driven pressure controls for fan, atomize, and pot pressure controls.

- Material flow rate sensor.

- Recipe greasing of spindle rotators and blower bearings

- Recipe lubrication of chain

- Custom part fixturing and masking.

- Stationary spindle operation.

- Canadian CSA certification. Service plans and options.

Trust Arnold Machine with Your Chain-On-Edge Needs

Arnold Machine understands that choosing the right coating system is crucial for your business. We offer a range of solutions and expert guidance to ensure you find the perfect fit for your needs. Our team is dedicated to providing exceptional service and support, from initial consultation to installation and beyond. Contact us today to discuss your coating system requirements and discover how we can help you achieve efficient and high-quality results.

Two Coat Chain-On-Edge FAQ

-

Can this system handle multiple coats or spray zones?

-

How customizable is the system?

-

How does the system ensure safety and compliance?

Featured Posts

Choosing Between a Single-Coat & Two Coat Chain-on-Edge Conveyor

Chain-on-Edge Anti-Corrosive Spray System