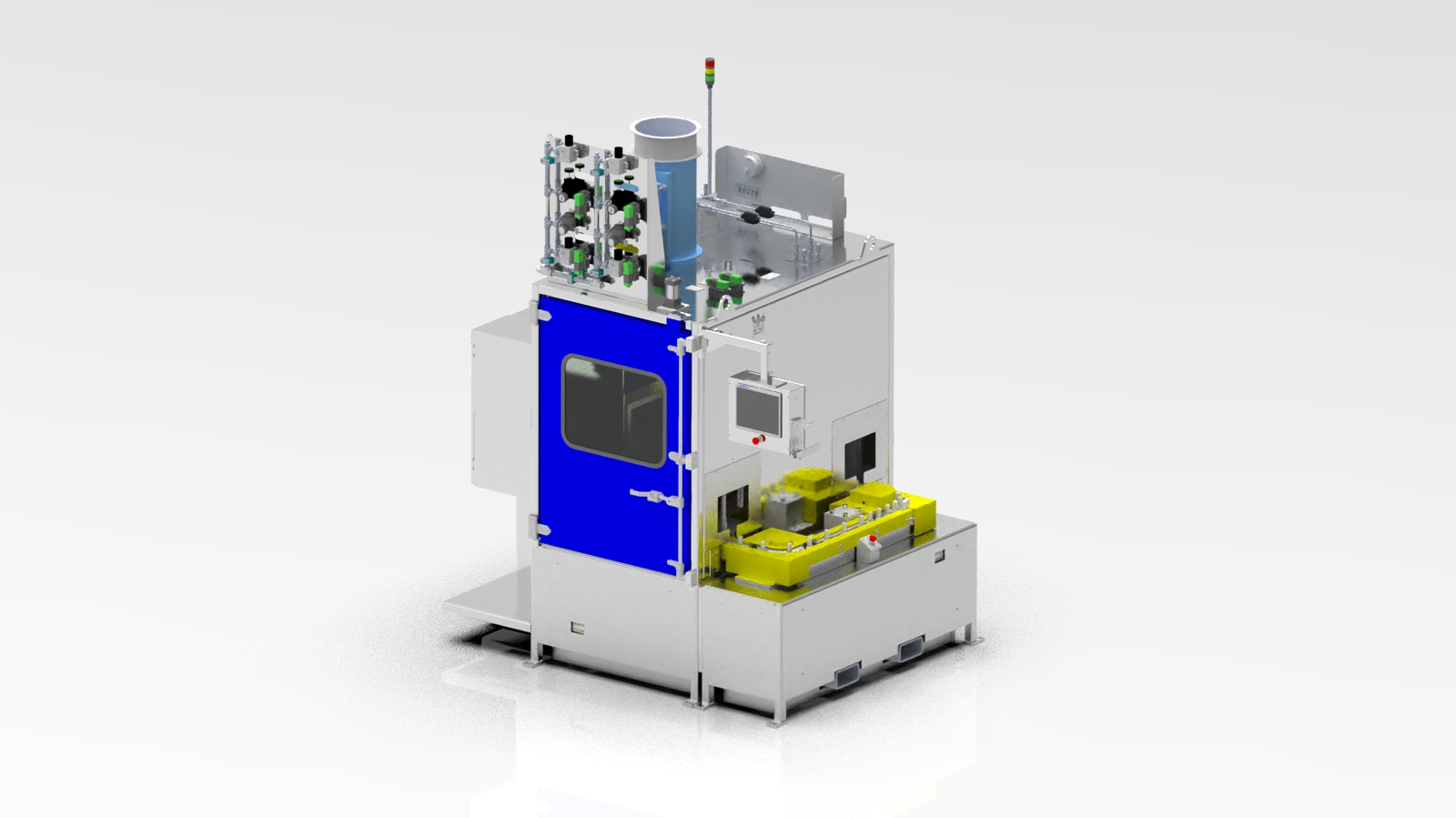

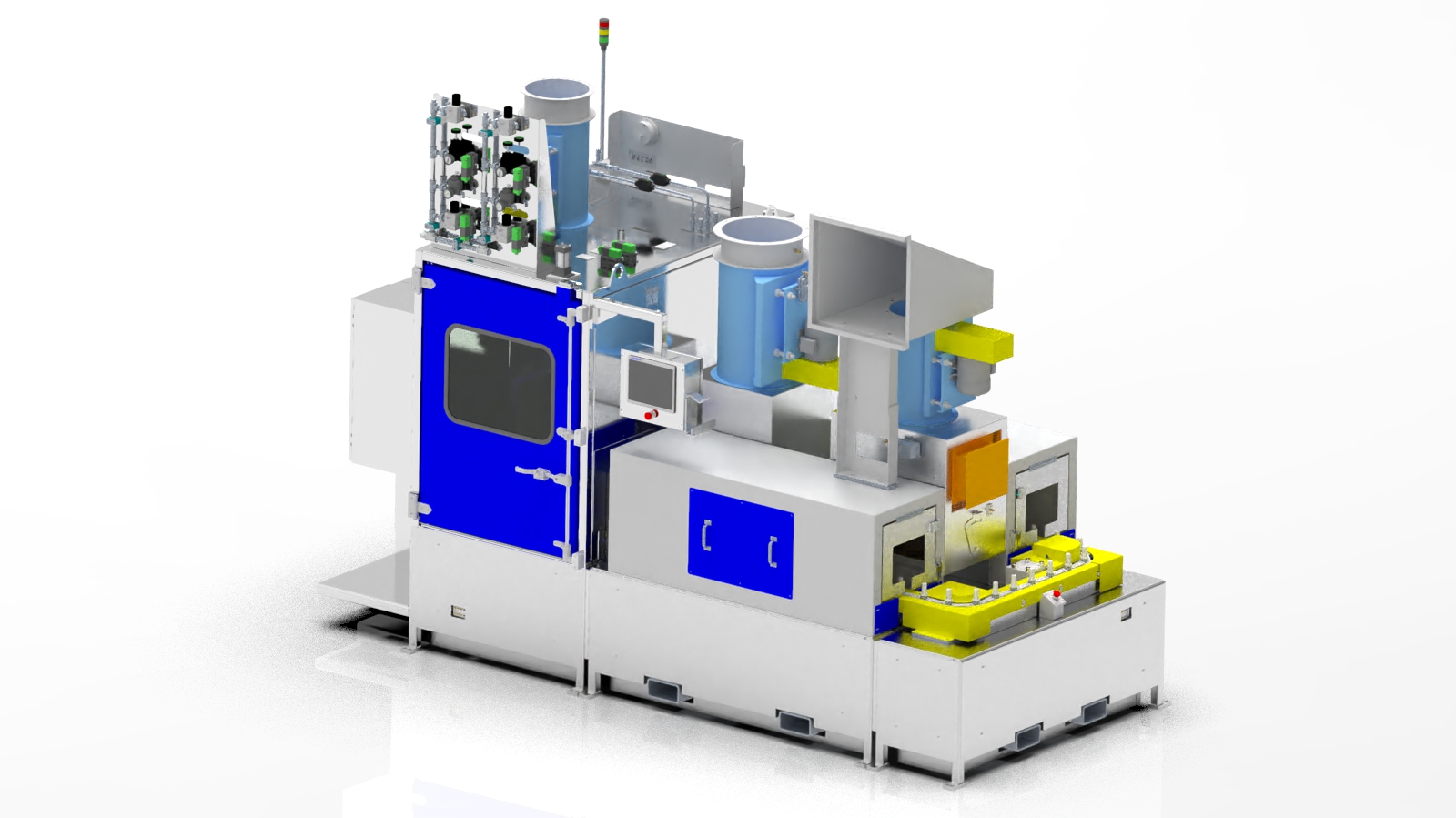

Single Coat Chain-On-Edge (CoE) Coating System

The Single Coat Chain-On-Edge Coating System automates the coating process, reducing manual labor while ensuring uniform thickness and high-quality results.

Designed for both high- and low-volume production, it features a rotate & spray application within a Class 1, Division 1 explosion-proof booth for maximum safety and efficiency.

Its servo motor-controlled chain drive enables continuous or indexed operation, while optimized air and fluid controls enhance repeatability and transfer efficiency.

Benefits of Two Coat Chain-on-Edge Coating Systems

How Single Coat Chain-on-Edge Coating Systems Work

The Single Coat Chain-on-Edge System is a compact and efficient coating solution designed to transport parts through a structured series of stations. Each station is crucial in ensuring a precise and consistent coating application. The system is engineered to apply a single coating material (either solvent- or water-based) throughout the process, offering a robust and reliable solution.

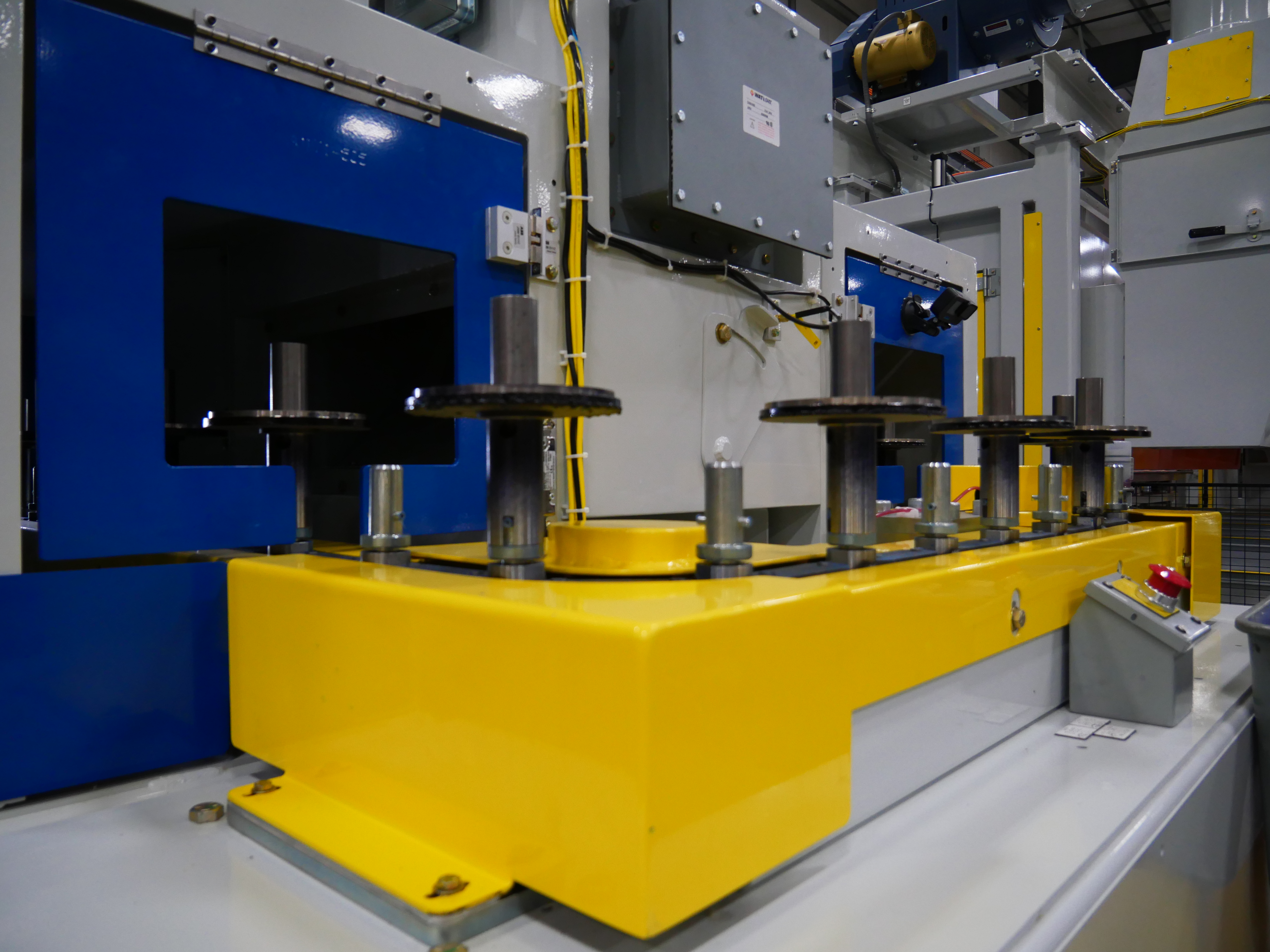

- Parts are manually loaded into the fixture and conveyed to the spray booth either in an indexing motion or constant speed. The parts will be conveyed through the oven if the optional heating module is included.

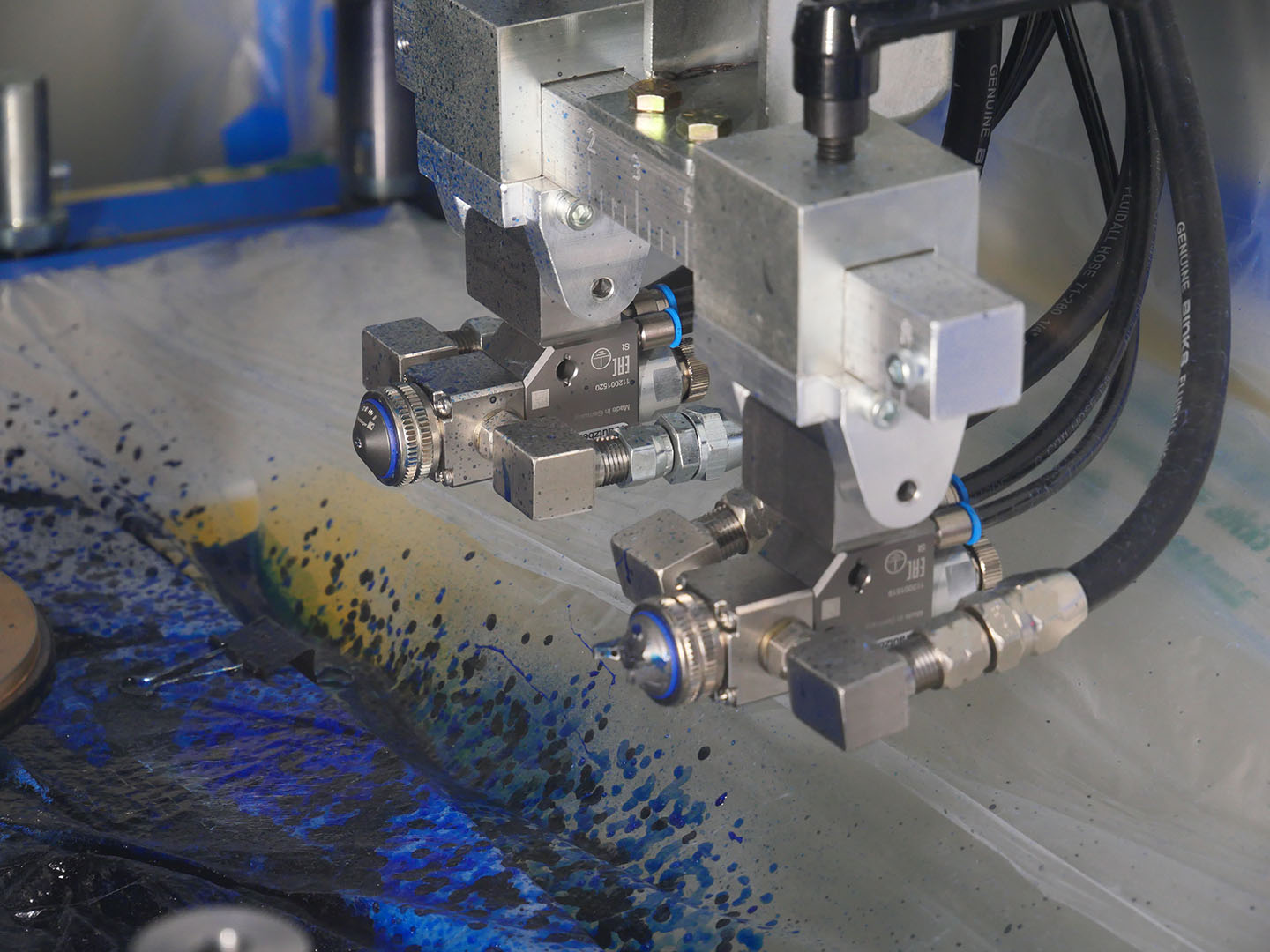

- The chain moves to the coating booth, where a mechanism rotates the spindle and part for the spray cycle.

- A single HVLP spray gun applies coating in either the standard fixed mounted position, single-axis servo-positioned, or robotic-positioned.

- The coated part moves throughout the coating booth and back to the operator for removal. The parts will again be conveyed through the oven if the optional heating module is included.

Common Applications

Chain-on-Edge (CoE) conveyors are specifically designed for coating straight or profiled cylindrical substrates that require inside or outside diameter coverage. These systems efficiently coat multiple surfaces of a part in a single pass, making them highly effective for various industrial applications.

The Single-Coat Chain-On-Edge Conveyor is optimized for high & low-volume production where repeatability and efficiency are critical. It is commonly used in automotive, industrial, and consumer goods manufacturing to apply rust preventive, adhesive, or lubricant coatings.

Ideal Substrates & Part Specifications:

- Suitable for aluminum, steel, or plastic components.

- Designed for parts ranging from 1 to 5 inches in diameter and up to 6 inches in height.

- Well-suited for consistent part sizes and shapes in both small and large production runs.

While CoE systems offer high efficiency and precision, it's essential to consider part size limitations and variations when selecting this coating solution to ensure optimal performance.

Specs

Part Size Capacities:

- 5 1/2 in. diameter x 8 in. tall in the full 6 in. center distance configuration

- Parts up to 10 in. in diameter and 8 in. tall can be accommodated by using every other spindle on a 12 in. center distance

Machine Dimensions:

- 10 ft. tall x 6 ft. wide x 8 ft. long (without the heating module)

- 14 ft. long without the optional heating module

Utility Requirements:

- 480 VAC - 3 phase - 60 Hz - 50 AMP power (150 AMP with heating module)

- 3/4 in., 60 PSI compressed air

- 1 in., 35 PSI fresh water supply

- 14 in. Exhaust Duct outside of the building

- Additional 14 in. exhaust duct is required with an optional heating module

Control System:

- NEMA 12 main control panel with sequester 480v main disconnect

- UL approved 24 VDC controls package with Allen-Bradley CompacLogix PLC and ProFace 10 in. touch screen control panel

- Red, yellow, green stack light

- Servo conveyor drive with options for constant motion or index and dwell

- Adjustable rotation speed

Features

- 24 spindles on 6 in. centers without the optional heating module

- 48 spindles on 6 in. centers with the optional heating module

- Single HVLP Spray Gun mounted on an Adjustable Fixed-Position mount

- Fluid control system includes:

- 5 gal stainless steel pressure pot with cart and lid stand

- Integrated fluid recirculation system

- Integrated fluid agitation

- Manual regulators for Fan, Atomize, & Pot pressures

- Arnold Machine’s 100% air capture spray booth design to prevent solvent-laden air from escaping the machine. NFPA Class 1, Division 1 explosion-proof

- Safety interlocked booth door with viewing window and timed open

- Water-based fire suppression system

- Filter change alert on the touchscreen

- Automatic chain tensioning

- Operator cycle start/stop & emergency stop, and emergency stop tunnel entry doors

- Forklift pockets

- Spray booth light

- Central lubrication point

- Carbon steel construction, powder-coated 7035 Machine Grey

- One-year warranty on parts and labor for components and workmanship.

Optional Items

- Dual tunnel heating module for pre-heat and post-heat

- 150° F max temperature

- 45kW electric heating element

- Non-sparking blower with variable speed drive

- 2 in. insulated construction

- Recipe driven, programmable vertical gun position

- Recipe driven robotic gun position or spray pattern

- This option includes an automatic gun cleaning feature

- Recipe driven controls for fan, atomize, and fluid pressure

- Material flow rate sensor

- Custom fixturing and masking

- Canadian CSA certification

- Service plans available

Trust Arnold Machine with Your Chain-On-Edge Needs

Arnold Machine understands that choosing the right coating system is crucial for your business. We offer a range of solutions and expert guidance to ensure you find the perfect fit for your needs. Our team is dedicated to providing exceptional service and support, from initial consultation to installation and beyond. Contact us today to discuss your coating system requirements and discover how we can help you achieve efficient and high-quality results.

Single Coat Chain-On-Edge FAQ

-

Is the system suitable for water and solvent-based adhesive & paint materials?

-

How customizable is the system?

-

How does the system ensure safety and compliance?

Featured Posts

Choosing Between a Single-Coat & Two Coat Chain-on-Edge Conveyor

Chain on Edge System for Adhesive Coating