Automatic Viscosity Bulk Mixing Stations

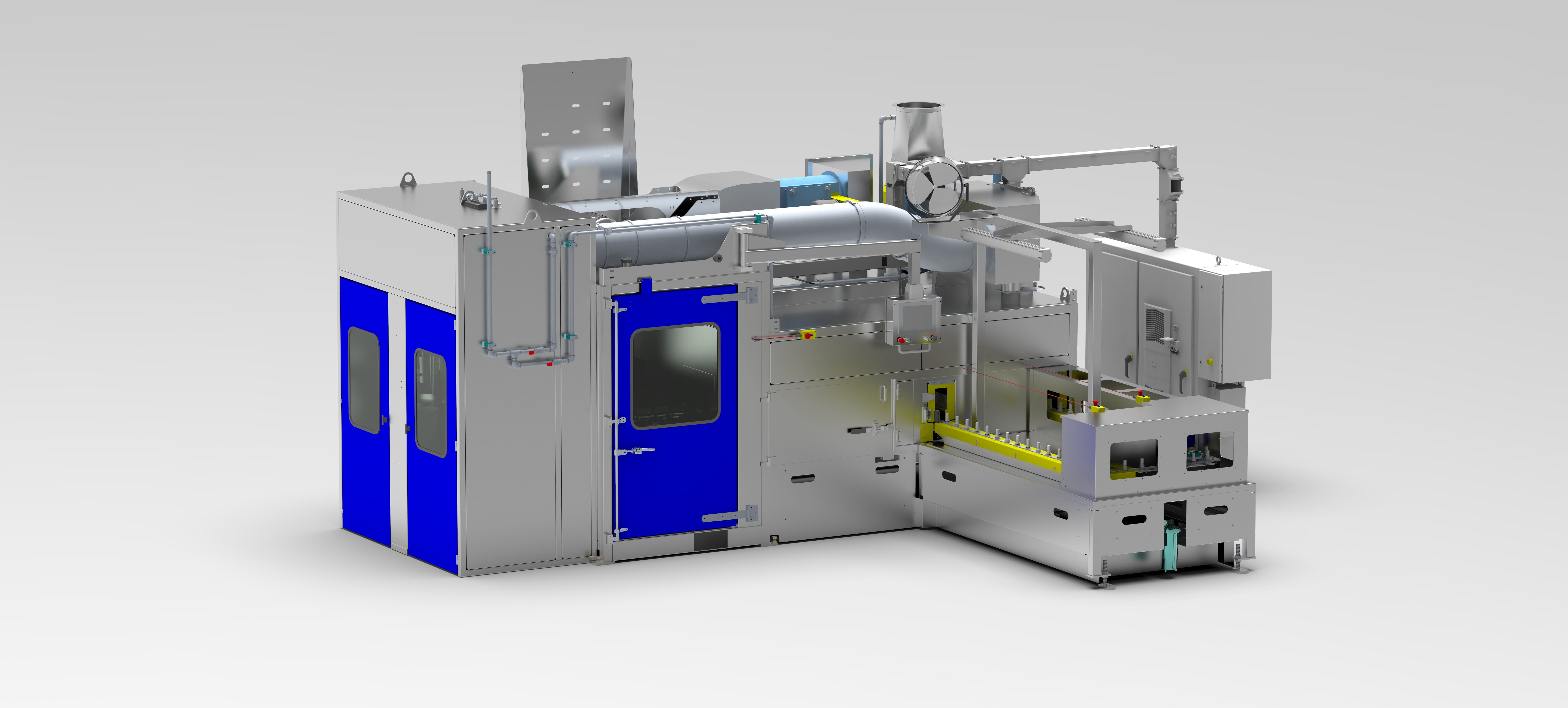

The Arnold Machine Automatic Viscosity-Controlled Bulk Mixing Station is engineered for flexibility and performance. Designed with a modular approach, it offers a wide range of customizable features to accommodate various spray application lines and mixing tank configurations.

In any automated spray process, achieving consistent quality while minimizing material waste is essential. One of the primary challenges is maintaining uniform material viscosity, which directly impacts coating performance and finish quality. Continuous agitation plays a critical role in preventing premature settling, reducing waste, and ensuring reliable, repeatable results.

Safety is also a top priority. The system is built to meet stringent safety standards, providing secure operation even when handling hazardous or flammable materials.

Benefits of Automatic Viscosity Bulk Mixing Stations

How Automatic Viscosity Bulk Mixing Stations Work

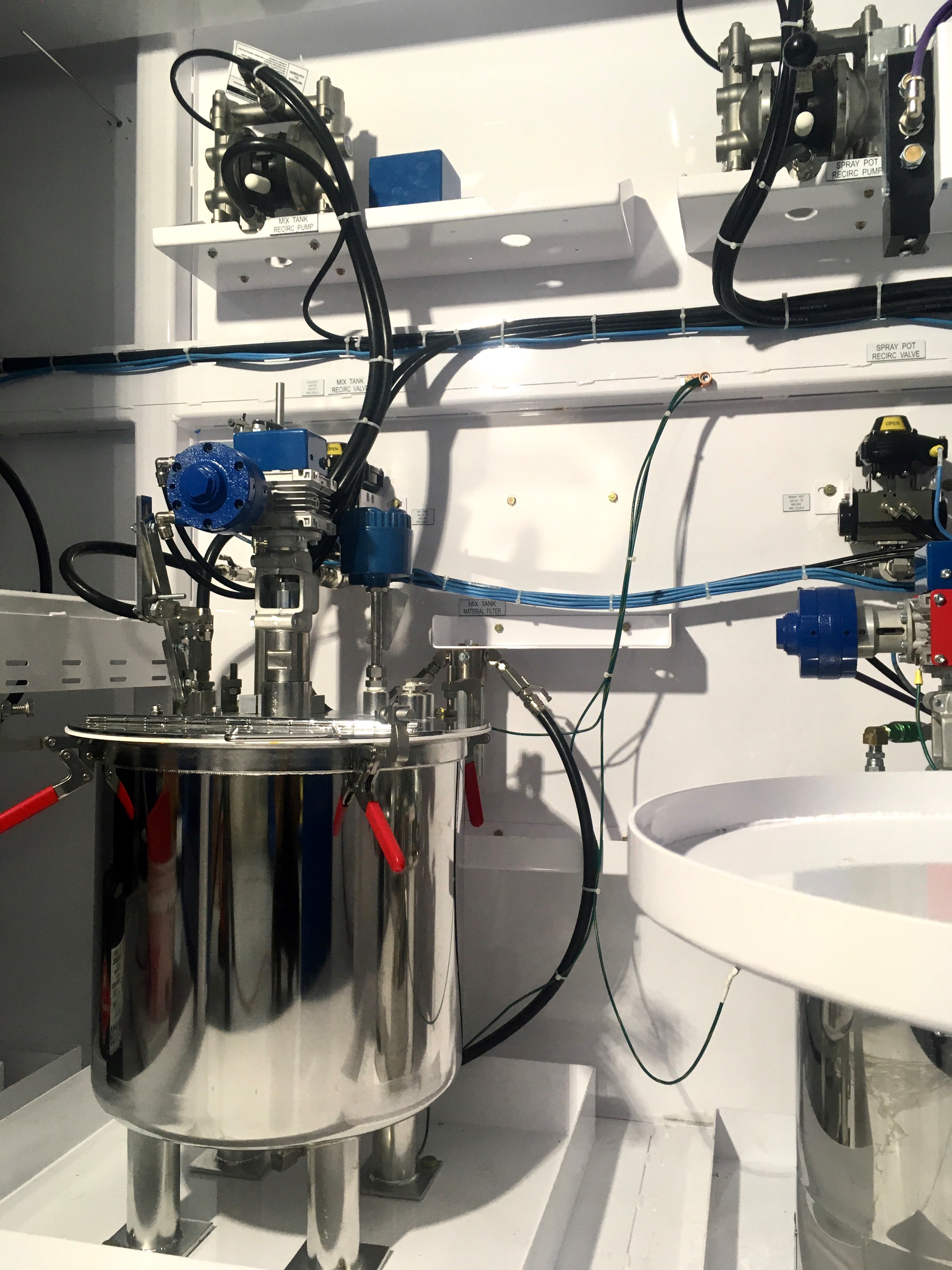

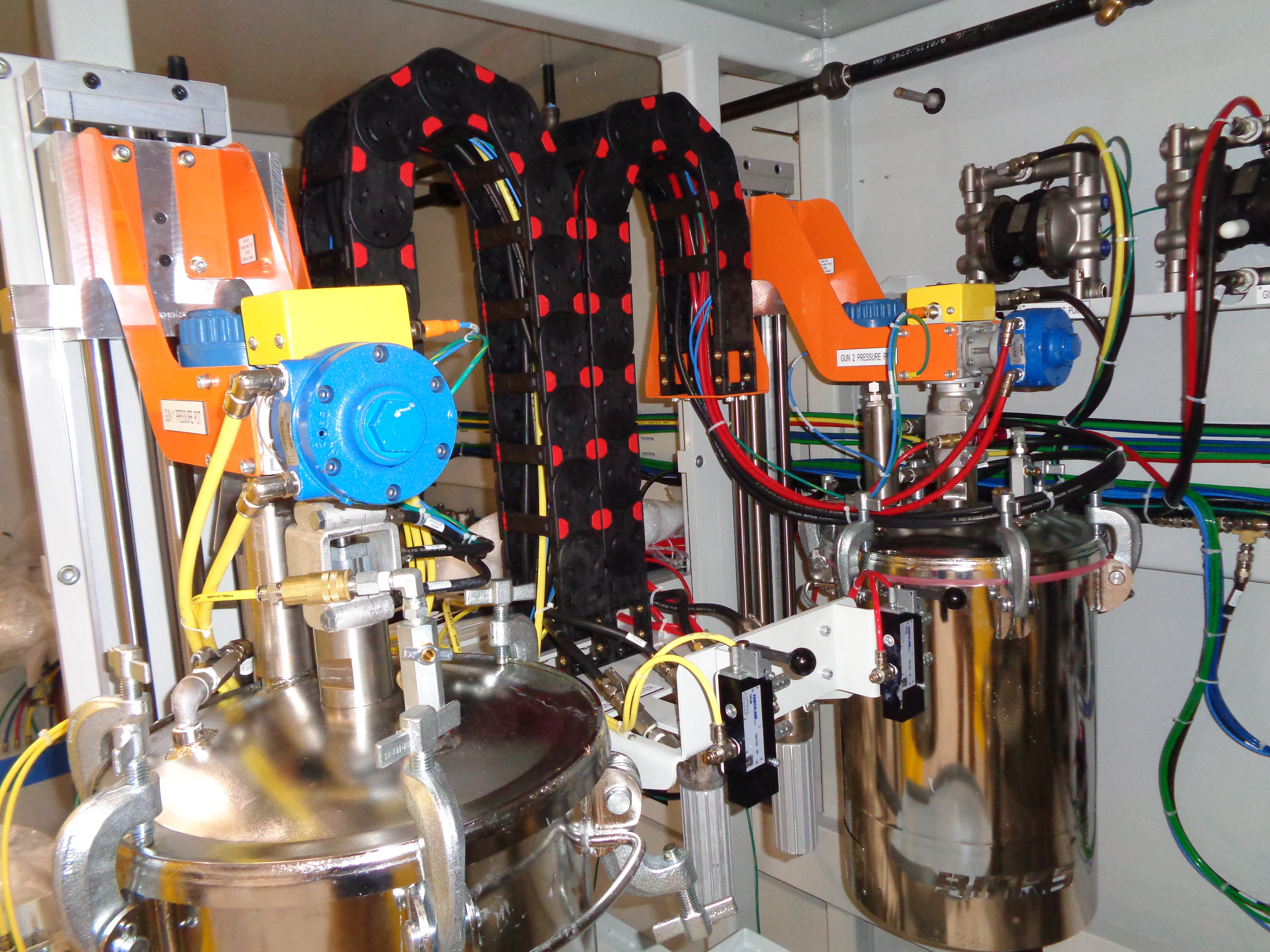

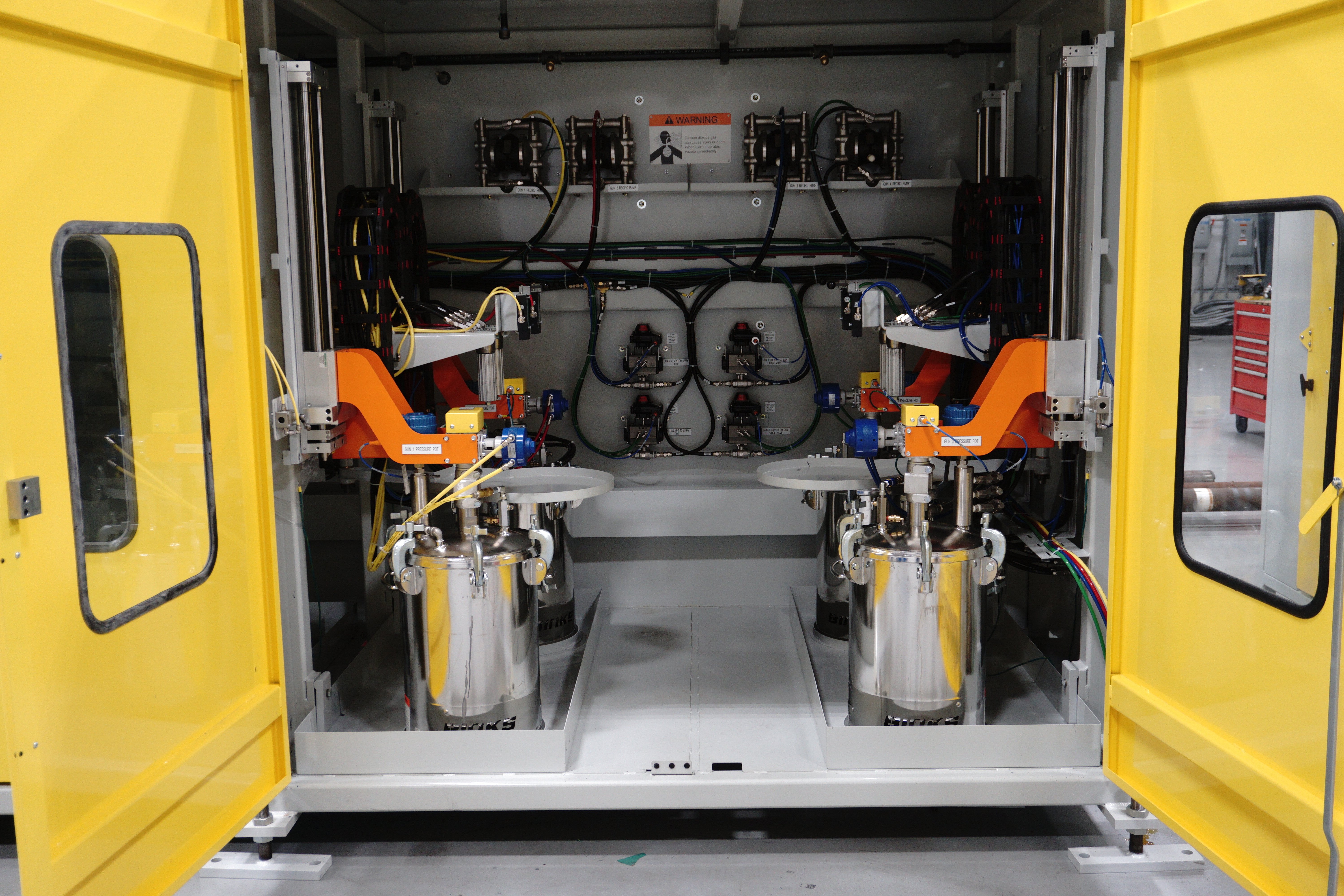

The process begins with 5-gallon buckets or 55-gallon drums of adhesive and solvent loaded into the cabinet. These containers are connected to fluid transfer pumps. A preset ratio of each material is then pumped into a separate mixing tank inside the cabinet.

The materials are agitated for a predetermined time to create a homogeneous mixture that is transferred through a viscometer to measure its viscosity. Based on the target viscosity setting, additional adhesive or solvent is continuously added to the mix until the desired setpoint range is achieved.

Standard Features & Benefits

- The machine is entirely made in the USA

- 20 Gallon stainless steel mixing tank with integrated agitator

- 5 Gallon part A material load station with pail cover and integrated agitation

- 55 Gallon part B load station with pickup tube

- Integrated pneumatic diaphragm pumps for part A & B

- Integrated viscosity control and level monitoring in the mix tank

- Fluid output filter module

- Integrated fluid recirculation system

- Integrated fluid agitation

- Arnold Machine 100% air capture design to prevent solvent-laden air from escaping the machine. NFPA Class 1, Division 1 explosionproof

- Access door with viewing window

- Water-based fire suppression system

- Filter change alert on the touch screen

- Carbon steel construction, powder coated 7035 Machine Grey

Specs

- Machine Dimensions

- (Single Material) - 10 ft. tall x 5 ft. deep x 6 ft. long

- Utility Requirements

- 120 VAC - Single Phase 60 Hz - 20 AMP power

- 3/4 in., 60 PSI compressed air

- 1 in., 35 PSI fresh water supply

- 6 in. Exhaust Duct outside of the building (if desired)

- Control System

- NEMA 12 main control panel

- UL approved 24 VDC controls package with Allen-Bradley CompacLogix PLC and ProFace 10in. touch screen control panel

- Red, yellow, green stack light

Optional Items

- Dual stations for mixing two materials at the same time

- Internal cabinet lighting

- Canadian CSA certification

- Service plans and options

Common Applications

Automatic Viscosity Bulk Mixing Stations are versatile systems ideal for various applications involving adhesives, paints, and other coatings.

These stations are commonly integrated with standalone automated coating systems to provide a consistent supply of properly mixed materials at the desired viscosity.

Trust Arnold Machine with Your Bulk Mixing Needs

At Arnold Machine, we understand the importance of precise and consistent material mixing for your coating processes. We design our Automatic Viscosity Bulk Mixing Stations to streamline your operations, reduce waste, and ensure optimal results. Our expertise in customized solutions and commitment to process control and safety make us the perfect choice for your specific bulk mixing needs.

Automatic Viscosity Bulk Mixing Station FAQ

-

What is the maximum amount of raw and mixed materials inside the cabinet?

-

How long does it take to mix a 20-gallon batch of material?

-

Does the system need to be connected to a spray machine, or can it be a central point for mixing materials?

Other Coating Systems and Related Machines

Chain-on-Edge Conveyors

Boost your profitability with our innovative CoE systems. Advanced robotics automate your processes to increase transfer efficiency and reduce labor costs.

Tumble Spray Coating Systems

Achieve unmatched protection and efficiency with our fully automated Tumble Spray systems. Experience 100% coverage, significant labor savings, and consistent results in your coating operations.

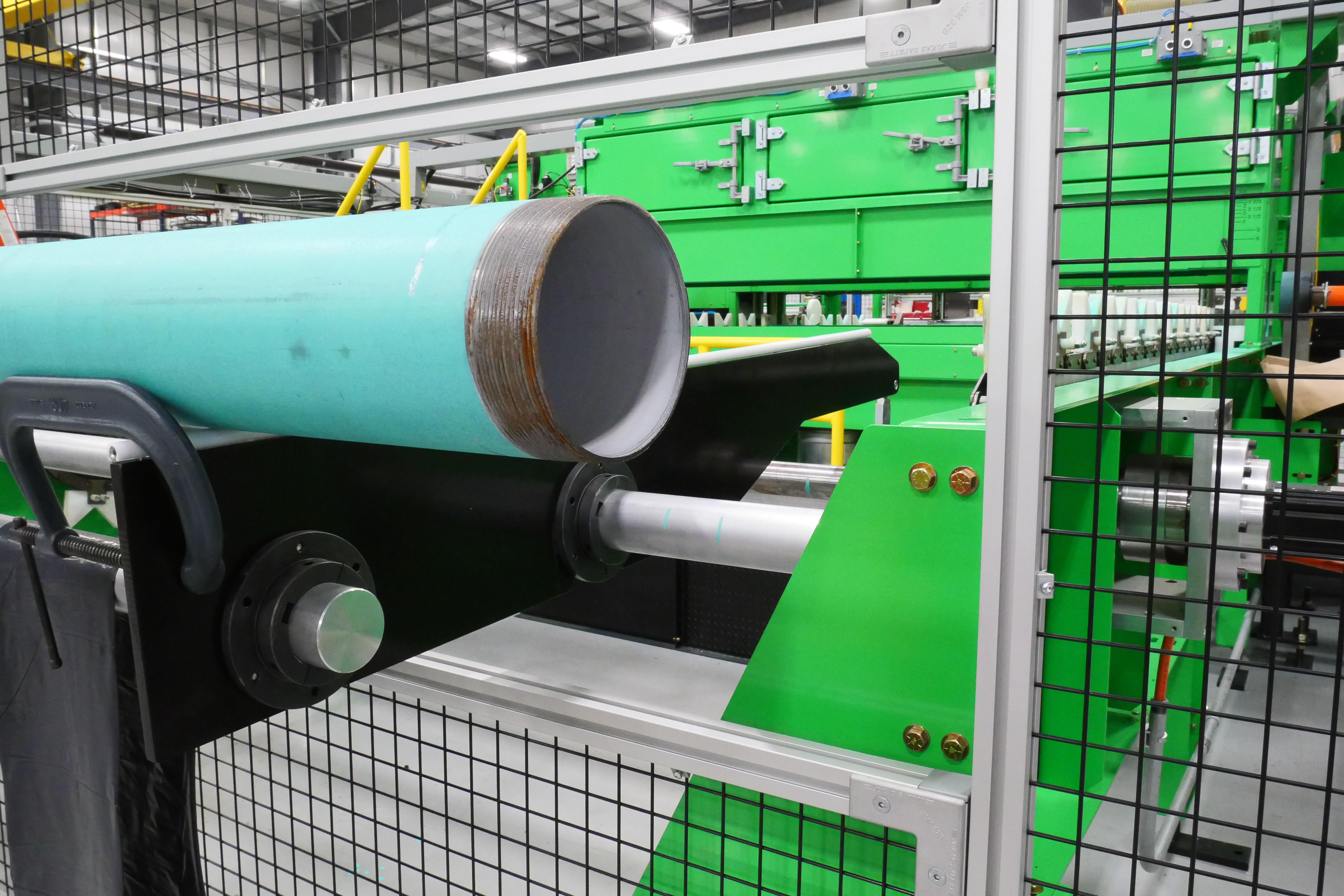

Roll Coater Systems

Our customized Roll Coater Systems seamlessly integrate into your existing processes, delivering consistent high-volume coating results. Experience unmatched throughput, minimal adhesive waste, and reduced labor requirements.

ID Tube Spray Machines

Protect your workforce and achieve superior tube coating efficiency with our automated ID Tube Spray Machines. Reduce cycle times, verify material usage, and eliminate harmful VOC exposure for your operators.