Tumble Spray Coating Systems

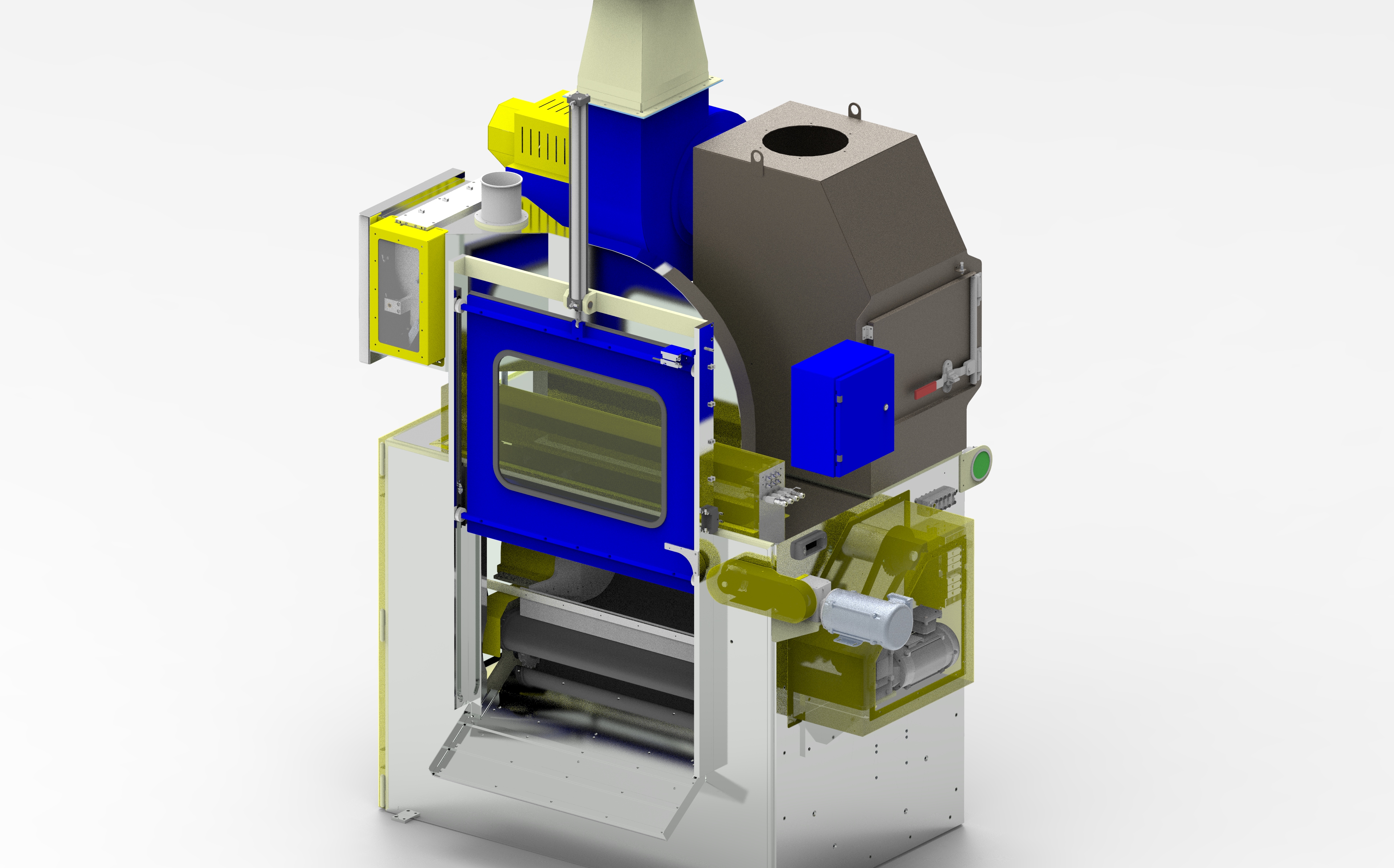

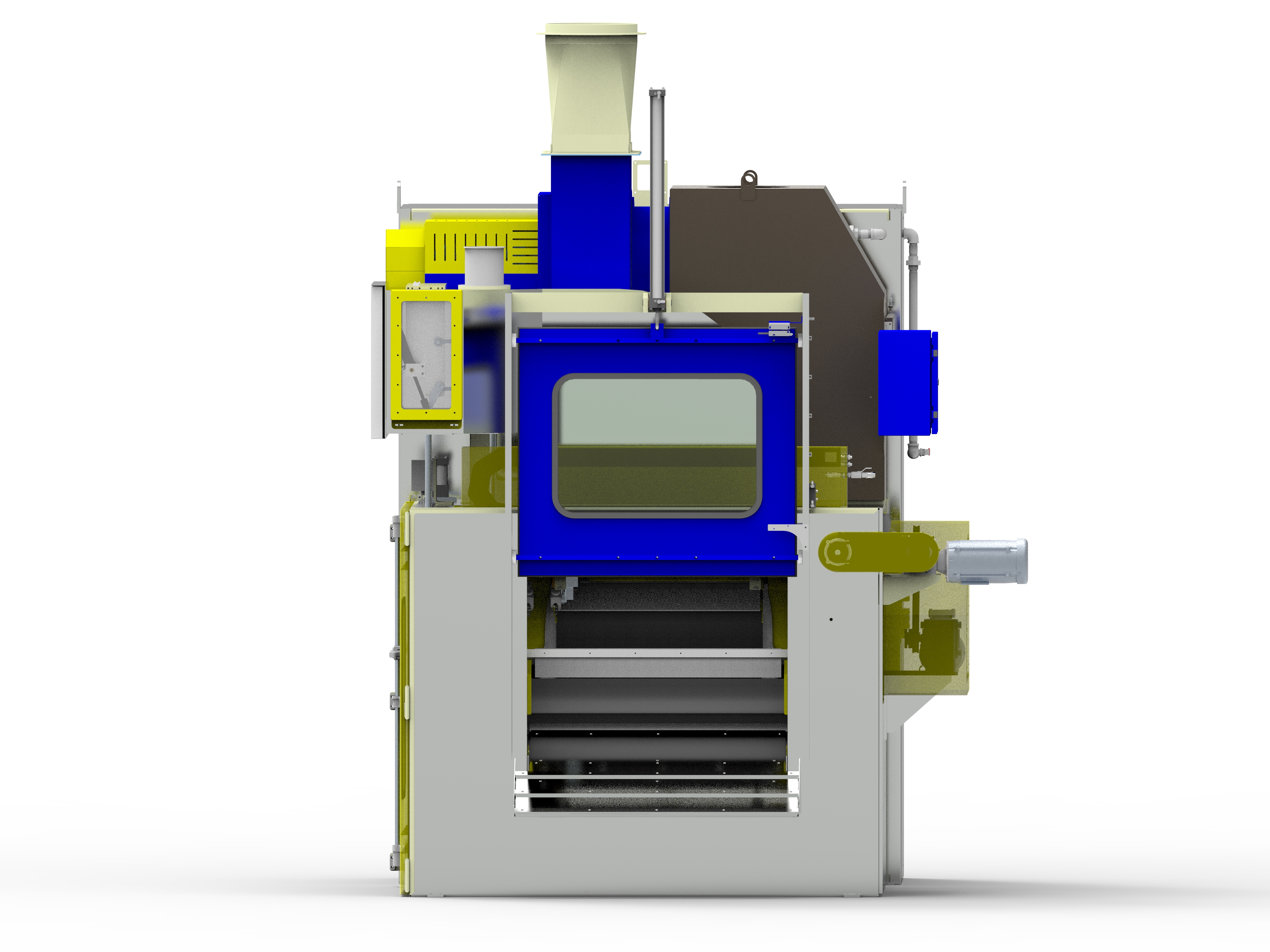

The Arnold Machine Tumble Spray Coating System is commonly used for parts that require 100% coverage. The machine can apply paint, adhesive, rust preventive, lubricant, or virtually any other solvent or water-based material needing to be sprayed. The system utilizes a tumble and spray coating application in a Class 1, Division 1 explosion-proof, fully enclosed spray booth and is designed for maximum transfer efficiency of coating materials through its air control design and fluid process control. The system can apply two different materials utilizing a reciprocating spray gun shuttle. The parts are tumbled on a mesh belt while being sprayed. The belt is easily removable from the system for cleaning.

The spray chamber is 16” deep by 40” wide. Part size and batch capacities will vary based on geometry and tumble performance. Each different part configuration will require a recipe to be developed in the machine’s touchscreen.

Benefits of Tumble Spray Coating Systems

Standard Features & Benefits

- Completely manufactured in the United States

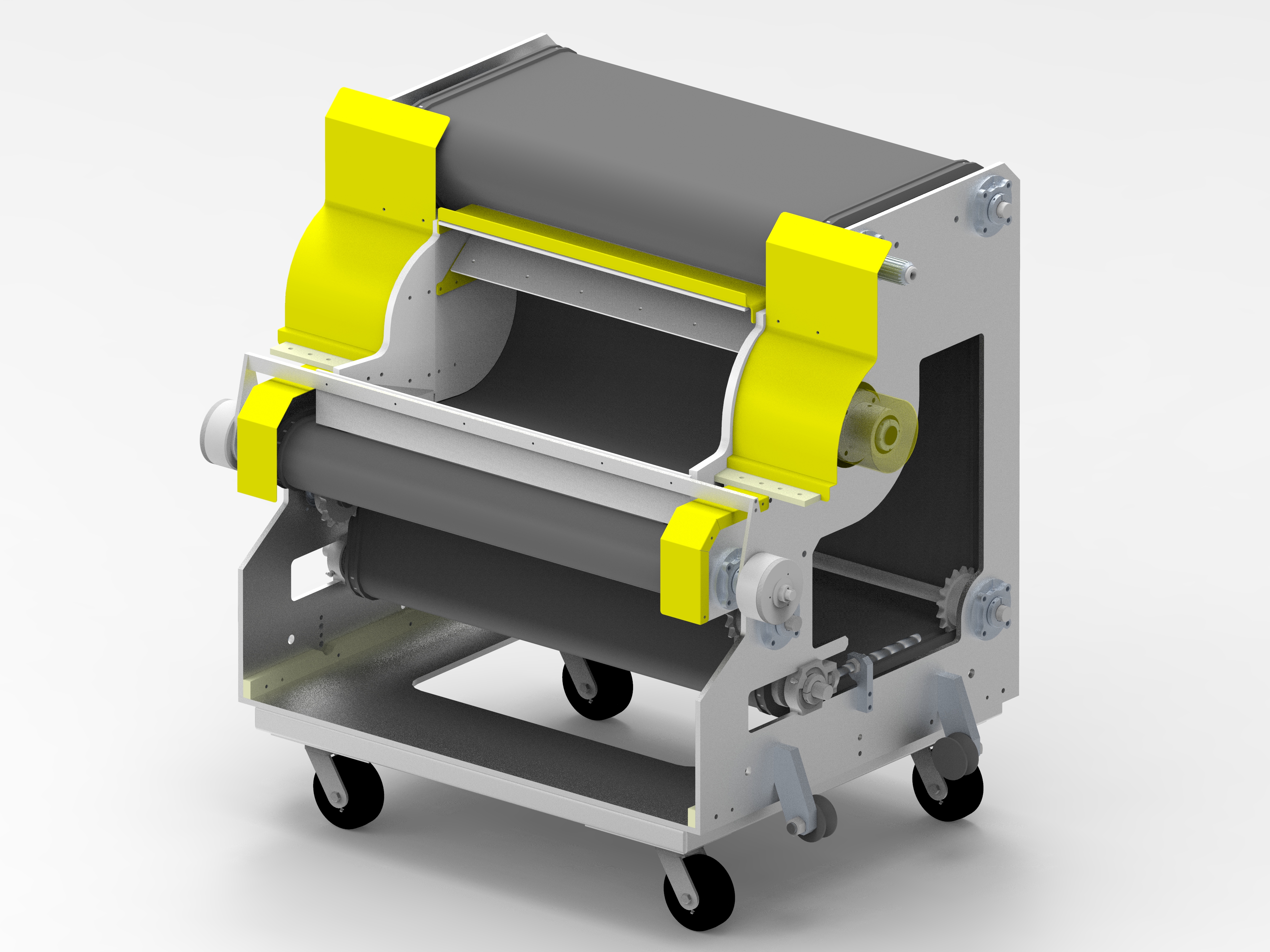

- Removable tumble belt mounted on a cart

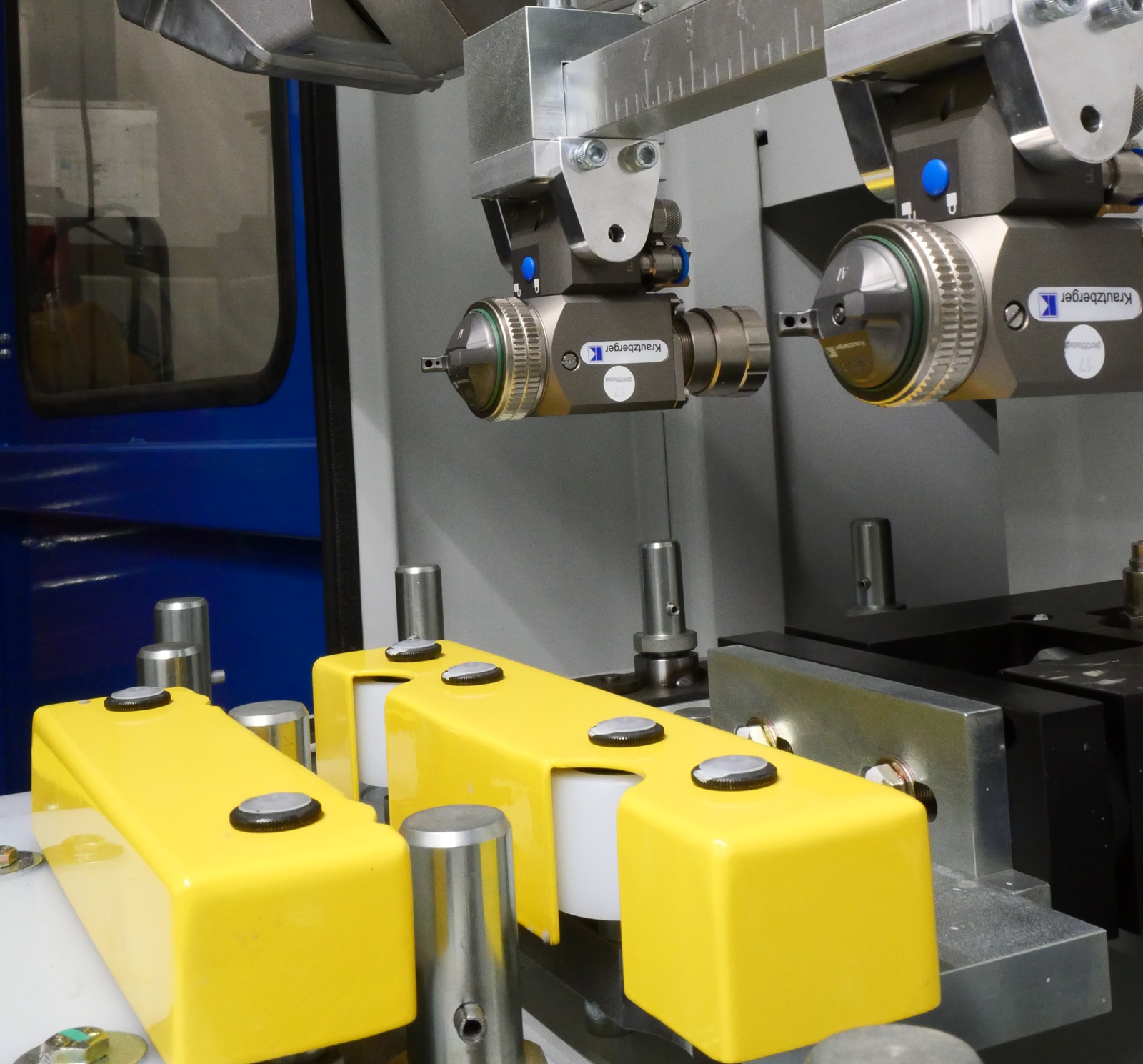

- Single HVLP Spray Gun mounted on a reciprocating shuttle

- A second gun is optional for a two-coat system

- Fluid Control System includes:

- 5 gallon stainless steel pressure pot with cart and lid stand

- Integrated fluid recirculation system

- Integrated fluid agitation

- Manual regulators for Fan, Atomize & Pot Pressures

- Heating Module

- Programmable forced heating air coating dryer (150F max air temperature)

- Arnold Machine 100% air capture spray booth design to prevent solvent-laden air from escaping the machine. NFPA Class 1, Division 1 explosion-proof

- Safety interlocked booth door with viewing window

- Water-based fire suppression system

- Filter change alert on the touchscreen

- Operator cycle start/stop & emergency stop

- Ability to create and save the multi-point, custom configuration recipe in the touch screen

- Integrated lifting eyes

- Spray booth light

- Carbon steel construction, powder-coated 7035 Machine Grey

Common Applications

The Tumble Spray Coating System is designed to handle a wide variety of coating needs across industries. The average batch weight is 20-30 lbs — it must fit in the 16” deep x 40” wide spray chamber.

Typical applications include:

- Adhesive Application – Spraying adhesives for bonding or assembly processes.

- Paint & Protective Coatings – Delivering consistent paint or solvent-based finishes for enhanced durability and appearance.

- Specialty Coatings – Handling unique solvent or water-based materials for custom manufacturing requirements.

- Rust Prevention – Applying rust inhibitors to metal components for long-term protection.

- Lubrication – Evenly coating parts with lubricants to reduce friction and wear.

Specifications

- Machine dimensions – 11ft tall x 8.55ft wide x 5.5ft deep

- Utility requirements;

- 480 VAC – 3 phase - 60 Hz – 100 AMP power

- 3/4”, 60 PSI compressed air

- 1”, 35 PSI fresh water supply

- 14” Exhaust Duct outside of the building

- Control system;

- NEMA 12 main control panel with sequester 480V main disconnect.

- UL-approved 24 VDC controls package with Allen-Bradley CompacLogix PLC and ProFace 10” touch screen control panel.

- Red, yellow, green stack light

- Adjustable tumble and spray gun reciprocating speed

Optional Items

- Dual spray for two-coat applications.

- Spare tumble belt cart.

- Three belt options, dependent on part size.

- Recipe-driven pressure controls for fan, atomize, and pot pressure controls.

- Material flow rate sensor.

- Canadian CSA certification.

- Service plans and options.

Trust Arnold Machine with Your Tumble Spray Needs

Arnold Machine understands that choosing the right coating system is crucial for your business. We offer a range of solutions and expert guidance to ensure you find the perfect fit for your needs. Our team is dedicated to providing exceptional service and support, from initial consultation to installation and beyond. Contact us today to discuss your coating system requirements and discover how we can help you achieve efficient and high-quality results.

Tumble Spray Coating System FAQs

-

What types of materials can the Tumble Spray Coating System apply?

-

Is a Tumble Spray Coating System suitable for different part sizes and shapes?

-

How easy is a Tumble Spray Coating System to clean and maintain?